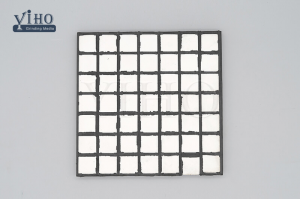

2 in1 or 3 in 1 Composite Ceramic Wear Plate

Why are ceramic wear plates needed?

-Superior wear resistance of high alumina ceramics.

-Energy-absorbing rubber cushions, more impact resistant.

-Extend wear life of your equipment, reduce maintenance and down time.

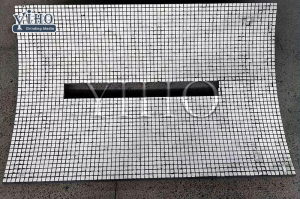

Equipment like conveyor transfer chutes, bins, hoppers or defectors usually suffer wear and impact attack from material handled, so it is necessary to line the equipment with wear resistant materials.

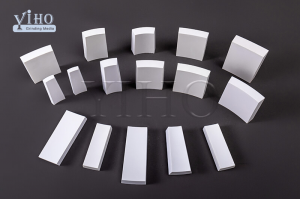

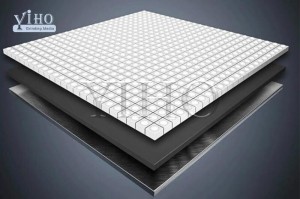

Composite ceramic wear plate, also called ceramic rubber wear plate, is a combination of high alumina ceramic tiles and rubber, it combines excellent abrasion resistance of high alumina ceramic and energy-absorbing of flexible rubber.

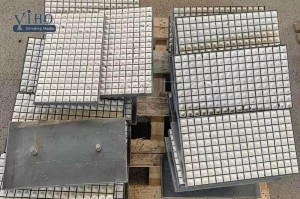

We have a lot of experience in producing rubber ceramic wear plates, special and advanced production process make sure excellent bonding between ceramic tiles and rubber. And our ceramic wear plates prove high quality in real world.

Installation

1. Ceramic wear plate with steel and studs can be bolted to equipment surface directly.

2. Ceramic in rubber only is also available. Ceramic rubber wear plate can be produced with CN bonding layer instead of steel and studs. Such ceramic wear plate can be bonded to chute or hopper directly.

Applications

Coal, Iron Ore, Coke, Sinter, etc.

Hot Tags: composite ceramic wear plate, china,manufacturers, suppliers, factory, customized, price, free sample, Double Seal Skirting Rubber, Alumina Ceramic Rubber Lining, Lining Rubber, Chute Ceramic Wear Liner Tile, Wear Resistant Ceramic Liner, Ceramic Wear Panels