Abrasion& Anti impact Ceramic Skirting Canoe Liners

Product Structure:

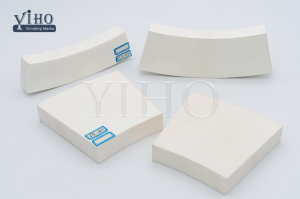

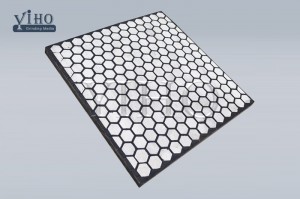

Solid Rubber or Ceramic / Rubber with steel backing plate and Tee Bolt slots for easy mounting means the entire wear face is solid with no holes to catch material and cause premature wear or bolt deterioration. Liners can be adjusted easily up or down to achieve the best fit.

YIHO can supply wear and skirting solutions for all types of material conveyance wear and impact areas. Custom liners are available for specialty applications such as wood and food processing and handling.

Examples of Use

· Conveyor Skirting

· Chutes

· Hopper wear areas

· Impact protection

· Material transfer points

· Overhead conveyor lines

· Primary impact areas

· Rail and Port loading terminals

· Rock boxes

· Screen Deck protection

· Screen discharge areas

· Screen undersize chutes

Features

· Highly effective particularly where material is being bulk loaded onto the conveyor to control the material until it becomes stable.

· The liners are steel backed and made to fit existing loading stations.

· They are manufactured to conform to the belt with the ability to adjust the height to fit the belt and maximize the liner life.

· The rubber thickness varies and ceramics can be added to fit the application.

· In load-zones with high tonnage rates, Canoe Liners significantly reduce spillage, dust and wear.

· Designed specific to your application, then custom manufactured.

· Each metal-backed Canoe Liner comes with the ability to adjust the height to fit your conveyor belt.