Abrasion & lmpact resistant Ceramic Wear Linings

-

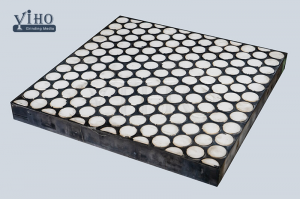

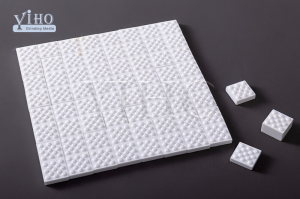

Engineering Wear Ceramic Matrix

Abrasion is always unavoidable in the processing and transport of bulk materials. The falling material flow causes particularly strong impact. We offer our customers best solutions with the high-quality ceramic wear matrix(with/without steel plate and bolt), in order to achieve an optimal result in increasing the impact resistance and reducing the abrasion and noise.

-

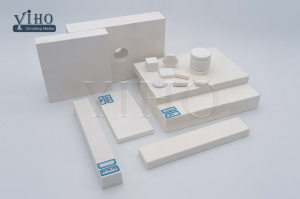

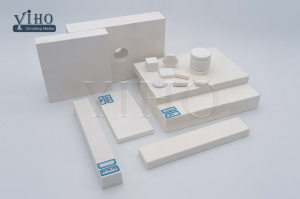

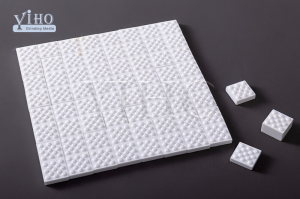

Dry Pressed Alumina Wear plate

Wear Plates are designed and manufactured for their specific intended application, ensuring the correct plate is always recommended and installed.

-

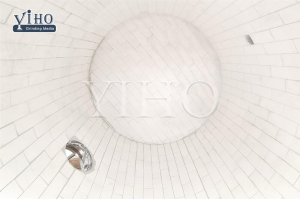

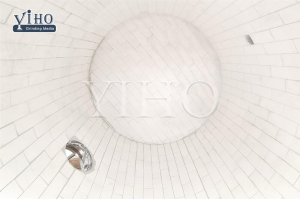

Direct Manufacturer of 92% and 95% Al2O3 ceramic lining ball mill brick

Yiho uses high quality, fine-grain 92% / 95% alumina brick with tongue and groove design. Bricks are secured and grouted with pure Portland cement or two-part epoxy. When it is time to reline a mill that is also a good time to check the bearings and drives components.

-

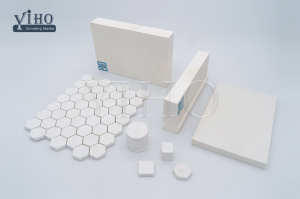

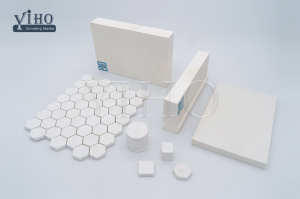

High Durability Customized Ceramic Wear Tiles for Increased wear resistance

YIHO offers a full range of shapes and sized ceramic tiles for your severe wear lining applications. YIHO can offer standard sized tiles (square and rectangular), hex tiles as well as custom shapes and sizes for your demanding application.

-

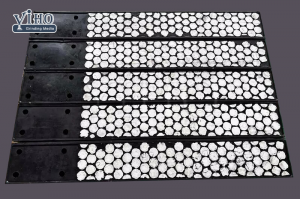

Conveyor Chute Lining Impact Liner Panel

Chute Linings are designed to be an integral part of a conveyor system. Our pre-engineered chute lining protects and cushions the chute from the material being handled; Skirt Liners prevents fugitive materials from escaping and damaging the conveyor loading areas. We can build, design, fabricate and install chutes, and also repair and re-align existing chutes.

-

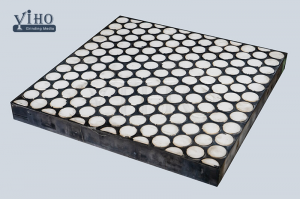

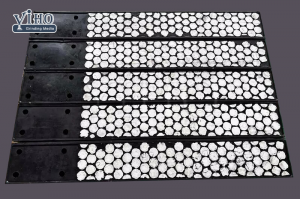

Coal Mining Ceramic Perforated Lining Plate Weldable Tile

YIHO supply and install a wide range of Alumina Wear Resistant Tiles for wear protection of all areas such as Chutes, Silos, Feeders, Bins, Launders, Dutching, Tanks, Bunkers, Hoppers, Underpans etc.

-

Chute ceramic Tile wear liner

The ceramic wear liner backed steel plates are hot vulcanized together with the high tensile strength nature rubber sheet and 3~10mm steel backing plate. As a result the ceramics wear liner will have both advantages of the rubber impact resistance and ceramic wear resistance.

-

Ceramic sleeve lined pipe fittings applied in mining industry

The big diameter ceramic sleeve is always a big problem for the ceramic tube manufacturers since it’s very difficult to control the deformation rate of the ceramic sleeve after it’s sintering .Also It will also need an advanced and big isostatic pressing machine to do this .So it will not only express the company’s production capability ,but company’s technology. Right now, our factory have owned both advantages which are wear resistant ceramic pressing facilities and technologies.

-

HEAVY WEAR PROTECTION Ceramic/rubber lining material

Ceramic composite rubber lining backed steel plate is the liner vulcanizing the ceramic and rubber into the steel plate. It can be connect with bolts and nuts or by welding the steel plate to do the connections. This product is normally the customized products, it can be made with different shapes, different thickness according to the working conditions.

-

Ceramic lined flexible rubber hoses

Ceramic tiles or Ceramic Balls are embedded into the inner tube of the Performer Ceramic hose. The ceramic material has been selected for its excellent abrasion resistance and allows at least 10 times longer lifespan compared to a rubber hose.

-

Ceramic pulley lagging tiles

Ceramic pulley lagging is a reliable solution for belt slippage problems, that conventional rubber lagging often cannot correct. In fact, it features the highest co-efficient of friction available in lagging materials which may be two to three times the friction of rubber in wet, muddy or dry conditions. Yiho ceramic pulley lagging is constructed from hundreds of individual ceramic tiles moulded in to a durable rubber backing.

-

Ceramic Hexagonal wear tile mats

YIHO manufactures a full range of high-density, fine-grain, wear-resistant alumina ceramic hex mats (hexagonal tiles). Our alumina ceramic is next to diamond in hardness, is 12 times more wear-resistant than carbon steel, and exhibits excellent corrosion resistance.