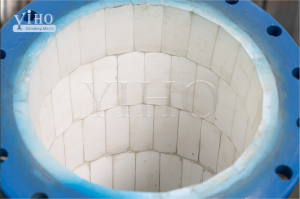

Abrasion Resistance Ceramic Lining Pipe

Detailed description

Alumina ceramic specifications

| Chemical Composition and Physical Properties | |||

| Composition | Al2O3 | ≥92% | ≥95% |

| Specific Density(g/cm3) | ≥3.60 | ≥3.65 | |

| HV Hardness HV20 N/mm2(MPa) | ≥980 | ≥1000 | |

| Rock Hardness HRA | ≥82 | ≥85 | |

| Bending Strength (MPa) | ≥220 | ≥220 | |

| Compressive strength (MPa) | ≥1050 | ≥1300 | |

| Fracture Toughness MPam 1/2 | ≥3.70 | ≥3.8 | |

| Wear Volume(cm3) | ≤0.25 | ≤0.20c | |

| Packing | Ctn box with pallets | ||

| Customized Tiles can be made. | |||

The most common applications of ceramic sleeve lined pipes

| Industry | Material |

| 1. Abrasive products | Grinding wheel granules |

| 2. Aluminium plants | Calcined alumina, bauxite, electrode, carbon, crushed bath |

| 3. Iron & Steel | Sinter dust, limestone, lime injection, coal, iron carbide, alloy additives |

| 4. Mineral wool & insulation products | Perlite, stone dust, refractory fibers, production wastes, dust from sawing operations |

| 5. Foundries | Molding sand, dust collection |

| 6. Glass plants | Batch, cullet, quartz, kaoline, feldspar |

| 7. Breweries, grain processing, feed mills | Corn, barley, soy beans, malt, cocoa beans, sunflower seeds, rice hulls, malting plants |

| 8. Cement | Clinker dust, limestone, cement, fly ash, coal, blast furnace slag |

| 9. Chemical plants | Caustic lime, fertilizers, lime dust, chrome ore, paint pigments, plastic pallets with glass fi bers |

| 10. Mineral mining plants | Kiln feed, ore concentrate, coal tailings, dust |

| 11. Coal fired power stations | Coal, fly ash, pyrites, slag, ash, limestone |

| 12. Coal mines | Coal dust, mine waste for backfi lling |

| 13. Technical carbon products | Technical carbon, dust, graphite for electrodes |

Write your message here and send it to us