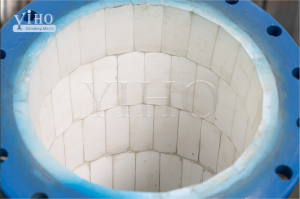

Abrasion-Resistant Pre-engineered Ceramic tiles Cyclone Linings

Introduction of Ceramic Lining

Cyclones handling abrasive products such as clinker dust or raw meal are often lined with YIHO abrasion-resistant alumina ceramic tiles to extend the cyclones' operating life.

These pre-engineered tile linings resist wear, abrasion, and corrosion from the materials being processed, reducing maintenance and downtime.

A relatively thick ceramic tile lining is critical in our Heavy-media Cyclones, as dense mineral matter can be very abrasive.

We offer our pre-engineered tiles in two different grades, with 25 to 38 mm (1” to 1.5”) thickness, to optimise wear life.

Pre-engineered and advanced processing techniques enable Yiho to manufacture ISO Pressed Alumina in a variety of geometries from simple to complex shapes. Combined with the appropriate attachment method, Alumina can overcome temperature limitations, impact and abrasion problems in many different environments. Weldable systems permit use of Alumina liners to temperatures in excess of 550OC, and are supplied with tapered hole, metal insert and an Alumina cap.

ISO Pressed Alumina Tiles offer three distinct benefits over standard ceramics

1. Tiles can be pre-engineered to minimise wear points and increase service life

2. Remarkable resistance to sliding and impact abrasion

3. Weldable systems for high heat, impact or corrosion environments

Other advantages include

• High hardness

• Extended wear life

• High temperature applications

• No dimensional variances during manufacturing

Material of the Cyclone Linings

92% Al2O3

95% Al2O3

T95% Al2O3

ZTA(Zirconia Toughened Alumina)

Tile Technical Data

|

Category |

HC92 |

HC95 |

HCT95 |

HC99 |

HC-ZTA |

ZrO2 |

|

Al2O3 |

≥92% |

≥95% |

≥ 95% |

≥ 99% |

≥75% |

/ |

|

ZrO2 |

/ |

/ |

/ |

/ |

≥21% |

≥95% |

|

Density (g/ cm3 ) |

>3.60 |

>3.65g |

>3.70 |

>3.83 |

>4.10 |

>5.90 |

|

HV 20 |

≥950 |

≥1000 |

≥1100 |

≥1200 |

≥1350 |

≥1100 |

|

Rock Hardness HRA |

≥82 |

≥85 |

≥88 |

≥90 |

≥90 |

≥88 |

|

Bending Strength MPa |

≥220 |

≥250 |

≥300 |

≥330 |

≥400 |

≥800 |

|

Compression strength MPa |

≥1050 |

≥1300 |

≥1600 |

≥1800 |

≥2000 |

/ |

|

Fracture Toughness (KIc MPam 1/2) |

≥3.7 |

≥3.8 |

≥4.0 |

≥4.2 |

≥4.5 |

≥7.0 |

|

Wear Volume (cm3) |

≤0.25 |

≤0.20 |

≤0.15 |

≤0.10 |

≤0.05 |

≤0.02 |

During their manufacture, we machine each ceramic tile in its “green” state, and then fire the lot to become interlocking, serialized liner components. Although this process is relatively expensive, the resulting increase in wear life pays for itself, and is one more reason why operations choose our Heavy-media Cyclones over other models that utilize flat tile.

Cyclones Dimension can be Manufactured

350/460/660mm/840mm/900mm/1000mm/1150mm/1250mm/1300mm/1450mm in diameter