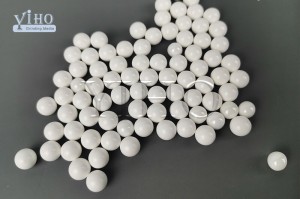

Alumina (Al2O3) Grinding Balls

Alumina grinding balls are widely used in ball mills as abrasive media for ceramic raw materials and glaze materials. Ceramic, cement and enamel factories as well as glass work plants use them because of their excellence of high density, their high hardness, and their high wear resistance. During the abrasive/grinding processing, ceramic balls will rarely be broken and the contamination factor is minimal.

Advantages

1.High wear-resistanceThe grinding balls wear-resistance is higher than common alumina balls, when it's working, the ball won't pollute the grinding materials, so it can keep the purity and improve the stability of grinded materials especially the ceramic glaze.

2.High DensityThe high density, high hardness and high grinding characters save the grinding time, enlarge the smashing room. So it can improve the grinding effciency.

Main specifications of Alumina (Al2O3) Grinding Balls Type 92

| Item | Value |

| AL2O3 | >92 % |

| SiO2 | 3.8 % |

| Fe2O3 | 0.06 % |

| TiO2 | 0.02 % |

| Other | 2.5 % |

| Water absorption | <0.01 % |

| Solid bulk density | >3.6 g/cm3 |

| Volumetric bulk density | 1.5-1.8 kg/l |

| Mohs hardness (Grade) | 9 |

| Attrition loss | <0.015 % |

| Colour | white |

Size

| Diameter(mm) | Φ 0.5-1 | Φ 2 | Φ 3 | Φ 5 | Φ8 | Φ 10 | Φ13 | Φ15-60 |

| Tolerance(mm) | / | ±0.3 | ±0.3 | ±0.3 | ±0.3 | ±0.3 | ±0.3 | Φ±0.5-2mm |

Other

We also have available all sizes of Al2O3 balls in between Φ3mm and including Φ60mm. Other contents of Al2O3 60%,75%, 92%, 99%.