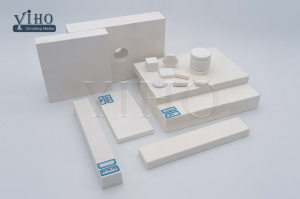

Anti wear Alumina ceramic interlocking Tile liner

92% alumina ceramic interlocking tiles are a type of modular flooring solution made from alumina ceramic material with a composition that is approximately 92% alumina and 8% other additives or binders. These tiles combine the benefits of alumina ceramic, including high hardness and wear resistance, with the convenience of an interlocking design for easy installation. Here's what you need to know about 92% alumina ceramic interlocking tiles:

-- Alumina Ceramic Composition: The alumina ceramic used in these tiles consists of approximately 92% alumina (aluminum oxide, Al2O3) and a smaller percentage of other materials that act as binders or additives. The high alumina content contributes to the tiles' exceptional hardness, wear resistance, and overall durability.

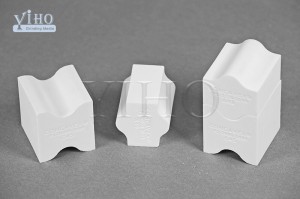

-- Interlocking Design: Like other interlocking tiles, these tiles are designed with edges that fit together, creating a secure and seamless surface without the need for adhesive or grout. The interlocking mechanism ensures stability and ease of installation.

Yiho offers wear solutions for iron and steel, mining, power, cement and other industries. We are your source for total custom piping solutions too! Complete planning, design, pricing, fabrication.

YIHO wear and abrasion resistant linings reduce downtime and maintenance and are marketed throughout the world. These wear resistant linings serve a variety of processing equipment including hydraulic and pneumatic components and pipes handling large quantities of bulk materials.

Alumina ceramic interlocking Tile Technical Data

|

Category |

HC92 |

HC95 |

HCT95 |

HC99 |

HC-ZTA |

ZrO2 |

|

Al2O3 |

≥92% |

≥95% |

≥ 95% |

≥ 99% |

≥75% |

/ |

|

ZrO2 |

/ |

/ |

/ |

/ |

≥21% |

≥95% |

|

Density (g/ cm3 ) |

>3.60 |

>3.65g |

>3.70 |

>3.83 |

>4.10 |

>5.90 |

|

HV 20 |

≥950 |

≥1000 |

≥1100 |

≥1200 |

≥1350 |

≥1100 |

|

Rock Hardness HRA |

≥82 |

≥85 |

≥88 |

≥90 |

≥90 |

≥88 |

|

Bending Strength MPa |

≥220 |

≥250 |

≥300 |

≥330 |

≥400 |

≥800 |

|

Compression strength MPa |

≥1050 |

≥1300 |

≥1600 |

≥1800 |

≥2000 |

/ |

|

Fracture Toughness (KIc MPam 1/2) |

≥3.7 |

≥3.8 |

≥4.0 |

≥4.2 |

≥4.5 |

≥7.0 |

|

Wear Volume (cm3) |

≤0.25 |

≤0.20 |

≤0.15 |

≤0.10 |

≤0.05 |

≤0.02 |

Alumina ceramic interlocking Tile Application

Alumina ceramic interlocking wear-resistant tiles are specifically designed to withstand high levels of abrasion and impact, making them ideal for applications where the flooring is subjected to severe wear and tear. Here are some key applications where alumina ceramic interlocking wear-resistant tiles are commonly used:

1. Mining and Minerals Processing:

Chutes and Hoppers: These tiles are often used to line chutes, hoppers, and other equipment that handle abrasive materials in mining and minerals processing. They protect the underlying structure from the impact and abrasion caused by the movement of rocks, ores, and other materials.

2. Screens and Sieves: Alumina ceramic wear-resistant tiles are used on vibrating screens and sieves to prevent excessive wear and ensure efficient material separation.

Bulk Material Handling:

3. Conveyors and Transfer Points: Conveyor belts and transfer points where bulk materials are transported can experience heavy abrasion. Alumina ceramic tiles are applied to these areas to extend the lifespan of the equipment and minimize maintenance.

4. Steel and Cement Plants:

Raw Material Handling: In steel mills and cement plants, where raw materials like iron ore, limestone, and coal are processed, these tiles are used to protect equipment from abrasion and impact during material handling and processing.

5. Power Generation:

Coal Handling: In power plants that use coal as a fuel source, wear-resistant tiles are used to line bunkers, chutes, and other areas where coal is handled. The tiles help prevent wear caused by the abrasive nature of coal.

6. Cement and Concrete Industry:

Clinker Handling: In cement plants, clinker is a coarse material produced during the cement manufacturing process. Wear-resistant tiles are applied to equipment handling clinker to prevent abrasion and prolong equipment life.

Pulp and Paper Industry: