Ceramic Cyclone Linings | Hydrocyclone Lining | Cyclone liner

Ceramic Cyclone Liner Introduction

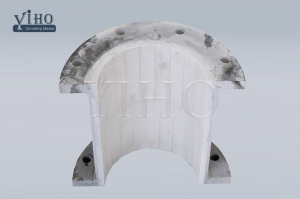

Seperator cyclone equipment is mainly abrasive damaged by handling material, YIHO can design ceramic cyclone liners according to customer's cyclone size and wear resistance requirement. ceramic tile liner cut and then composed .

These ceramic hydrocyclone liners are custom built in multiple sections using specially formulated joint technology and can be manufactured in a range of sizes from 0.5m to 1.5m. We can offer monolithic ceramic liners from ½” up to 30” internal diameters(ID).

FEATURES & BENEFITS

• A diverse portfolio of ceramic materials for different types of wear in the cyclone

• Extensive experience in lining design and applications

• Comprehensive ceramic shaping capabilities

APPLICATIONS

• Hydrocyclones

• Cyclone separators

Material of Cyclone liner

The separation and classification of even mildly abrasive particles can accelerate abrasion in hydro and air cyclones. The addition of corrosive elements frequently causing traditional materials to fail before expected.

1. Alumina

2. RBSiC silicon carbide

3. ZTA

|

Category |

HC92 |

HC95 |

HCT95 |

HC99 |

HC-ZTA |

|

Al2O3 |

≥92% |

≥95% |

≥ 95% |

≥ 99% |

≥75% |

|

ZrO2 |

/ |

/ |

/ |

/ |

≥21% |

|

Density (g/ cm3 ) |

>3.60 |

>3.65g |

>3.70 |

>3.83 |

>4.10 |

|

HV 20 |

≥950 |

≥1000 |

≥1100 |

≥1200 |

≥1350 |

|

Rock Hardness HRA |

≥82 |

≥85 |

≥88 |

≥90 |

≥90 |

|

Bending Strength MPa |

≥220 |

≥250 |

≥300 |

≥330 |

≥400 |

|

Compression strength MPa |

≥1050 |

≥1300 |

≥1600 |

≥1800 |

≥2000 |

|

Fracture Toughness (KIc MPam 1/2) |

≥3.7 |

≥3.8 |

≥4.0 |

≥4.2 |

≥4.5 |

|

Wear Volume (cm3) |

≤0.25 |

≤0.20 |

≤0.15 |

≤0.10 |

≤0.05 |

Dimensions can be customized by client’s request

Apart from the standard alumina ceramic tile, we can also manufacturer the pre-engineering ceramics to suit different equipment.

Ceramic Wear Liner Application

Apart from the standard alumina ceramic tile, we can also manufacturer the pre-engineering ceramics to suit different equipment.

We have our technical team who can help the client to choose the suitable wear resistant ceramic products ,and also we have the ability to design and make the CAD drawings according to the client’s wear application.

The Tailor-made ceramics had the advantage of low wear, high hardness and impact resistance , it widely used for the chutes, hoppers, bunkers , pipelines in the mining, power generation, steel plant, steel plant industries, it make cost effective performance and reduce the maintenance cost and down-time for the clients.