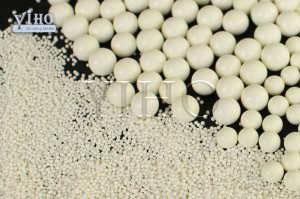

Ceramic grinding meida zirconia silicate grinding beads

Introduction of zirconia silicate grinding beads

Yiho Provides a comprehensive range of Ceramic Grinding Media, Including

- Alumina Grinding Ball with High Density and Medium Density

-Zirconium Toughened Alumina Gridning Ball

-Zirconium Silicate Grinding Ball

-Yttrium Stabilized Zirconia Grinding Ball

-Cerium Stabilized Zirconia Grinding Ball

Yiho Zirconium Silicate Beads are manufactured from world-class premium zircon (ZrSiO4) mineral in a special high temperature sintering process. Because of its outstanding breakage resistance and the advantageous price, this medium density bead is particularly suitable for use in large-volume agitated bead mills.

Until now, Yiho Zirconium Silicate Beads are successfully being used in all modern types of mills

zirconia silicate grinding beads Application

If you’re considering using Zirconium Silicate beads, then you need to be aware of some of its applications.

These areas are where you will get the most usage from this grinding media.

It’s worth noting that with Zirconium Silicate beads, performance doesn’t reduce even with daily use for grinding processes.

1.For use with nano materials, pharmaceutical products, and food products since there is minimal contamination associated with its use.

2.It is recommended for fine-grinding materials like zircon.

3.Ideal for milling ink, pigment, lighter paint shades, and coatings.

4.It also works well for color dispersion, which would otherwise get discolored if steel media got used.

5.They’re ideal for the superfine dispersal of chemical products like pesticides.

6.Recommended for use on solar cells, dielectric, semiconductors, batteries, and electronic materials.

7.They are excellent media for fine grinding and dispersing of minerals like kaolin, titanium dioxide, calcium carbonate, and agro- chemicals.

8.You can use it with ceramic glazes, magnetic materials, and cosmetics.

zirconia silicate grinding beads Key Benefits

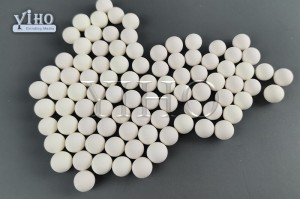

* Smooth working surface.

* Very High grinding efficiency for superfine grinding.

* Fine chemical stability & contamination-free to the grinded material.

* Extremely low wear rate.

* Excellent combination of toughness and hardness.

* Technical support provided to optimize milling conditions.

*High strength, high fracture toughness, high corrosion resistance and super smooth surface, etc.

*Large specific gravity, abrasion resistance, PPM abrasion grade, high hardness.

zirconia silicate grinding beads Chemical & Physical Property

|

ZrO2(%) |

≥50 |

|

AL2O3(%) |

≤16 |

|

SiO2(%) |

≤30 |

|

HV hardness(HV5) |

≥9.5GPa |

|

Water absorption |

<0.01 |

|

Bulk density(g/cm3) |

>4.08 |

|

Wear loss(g/kg.h) |

<1.2 |

|

Size |

Ø0.5-13mm |

|

Sphericity |

≥95% |

|

Color |

Ivory White |

Package

zirconia silicate grinding beads

Standard Dimension

Ø0.5mm-13mm

zirconia silicate grinding beads Packing

Different package as to meet different customer’s requirements.

Wooden Crates Drum Plastic Pallet Bulk Packing Plastic Bucket