CERAMIC LINED COMPONENTS AND BENDS

CERAMIC LINED COMPONENTS AND BENDS

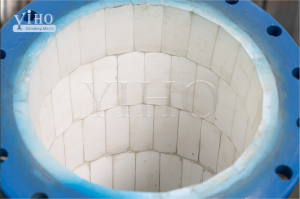

A ceramic-lined composite bend is a special type of bend that has a layer of ceramic material lining its interior. This bend design can fully leverage the advantages of both metals and ceramics, ensuring the strength and machinability of metals and the high temperature, wear-resistant, and corrosion-resistant properties of ceramics.

Hard & Compact ; Smooth & Inert ; Withstands High-Abrasion & Corrosion ceramic wear linings

In any of the process industries, especially steel and cement, corrosion and abrasion lead to significant downtime of the plant. Further, the useful life of the equipment itself may get impaired because of high abrasive nature of the materials being used. Thus, ‘wear mechanism’ results in shutdown, replacement, etc., which is costly, resulting in loss to the tune of millions of rupees. For resistance to wear, ceramic lined bends, straight pipes, etc., are ideal.

Based on years of practice, Kingcera introduced advanced technology from abroad, changed the ceramic fixing method from the traditional simple pasting to high-temperature resistant inorganic adhesive bonding, arching and stud welding triple fixing, and increased the use temperature to 750℃. Completely solve the problem of ceramic falling off at high temperature, greatly enhance the reliability, and generally extend the life of the equipment by 10-20 times.

FEATURES

High resistance to all types of chemicals

High resistance to sliding abrasion

Non wet ability and smooth surface results in easy flow of materials

Can withstand temperature of up to 200°C

Smaller ID of 100 mm can also be manufactured

Technical Details

• Ceramic Lined Bends are used for conveying material with high velocity.

• Ceramic lining are used for short radius Bend applications.

• Tile thicknesses range from 6 mm to 50 mm.

• Tube (cylinders) sizes range from 40 to 150 mm ID.

• Tiles Type: Plain / Tapered, Pastable / Weldeable, Pressed/Cast.

Materials Specifications

|

Category |

HC92 |

HC95 |

HCT95 |

HC99 |

HC-ZTA |

|

Al2O3 |

≥92% |

≥95% |

≥ 95% |

≥ 99% |

≥75% |

|

ZrO2 |

/ |

/ |

/ |

/ |

≥21% |

|

Density (g/ cm3 ) |

>3.60 |

>3.65g |

>3.70 |

>3.83 |

>4.10 |

|

HV 20 |

≥950 |

≥1000 |

≥1100 |

≥1200 |

≥1350 |

|

Rock Hardness HRA |

≥82 |

≥85 |

≥88 |

≥90 |

≥90 |

|

Bending Strength MPa |

≥220 |

≥250 |

≥300 |

≥330 |

≥400 |

|

Compression strength MPa |

≥1050 |

≥1300 |

≥1600 |

≥1800 |

≥2000 |

|

Fracture Toughness (KIc MPam 1/2) |

≥3.7 |

≥3.8 |

≥4.0 |

≥4.2 |

≥4.5 |

|

Wear Volume (cm3) |

≤0.25 |

≤0.20 |

≤0.15 |

≤0.10 |

≤0.05 |