Ceramic lined flexible rubber hoses

PERFORMER CERAMIC Solution

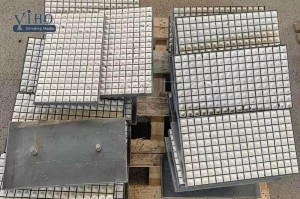

Ceramic tiles or Ceramic Balls are embedded into the inner tube of the Performer Ceramic hose. The ceramic material has been selected for its excellent abrasion resistance and allows at least 10 times longer lifespan compared to a rubber hose.

ceramic-lined flexible hoses are ideal for use in highly aggressive services where conventional rubber hose, expansion joints, or bellows connections require frequent replacement. YIHO hoses may also be used to isolate mechanical vibration or to connect non-stationary equipment.

Dry abrasion line of powder delivery

(Sand, grid, powdered coal, grain, cement and other fine powder)

For both delivery and suction

ceramic-lined flexible hoses Features

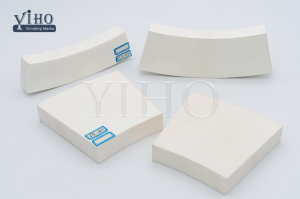

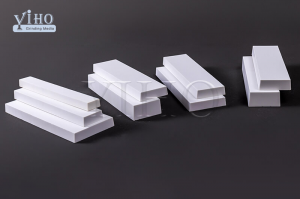

* Abrasion Resistance Composite of aluminum ceramics and rubber with high elasticity and strength for inner material.

* Excellent abrasion resistance against dry abrasion.

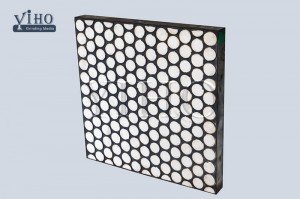

* Inner Rubber Layer, Inner rubber is complied by composite of ceramic balls (diameter ø3 to ø10) or Hex ceramic tiles and binder rubber with strong adhesion.

* Ceramic lining is 12 times more wear-resistant than stainless steel

* Impact resistant - virtually impossible to destroy the ceramic segments

* Flexible - minimum bend radius is roughly 12 times the hose I.D.

* Corrosion-resistant - compatible with most chemicals found in slurries

* Wide variety of end-connections

* Purchase any continuous length up to 65 feet

ceramic-lined flexible hoses Technical Specifications

Size Range: 1" to 12" I.D.

Pressure Rating: 150 psig.

Temperature Range: -100° F to 250° F

End-Connections: Flanged, plain, etc.

ceramic-lined flexible hoses Standard Specification

Working Pressure: 0.98MPa, Max. Length: 10m

ceramic-lined flexible hoses Applications

Hydraulic suction or discharge of highly abrasive material.

|

N.D. |

in. |

I.D.mm |

O.D.mm |

Weight kg/m |

|

25 |

1 |

25.4 |

52 |

3.7 |

|

32 |

2001/1/4 |

31.8 |

58 |

4.2 |

|

40 |

2001/1/2 |

38.1 |

66 |

5.1 |

|

50 |

2 |

50.8 |

79 |

6.1 |

|

62 |

2002/1/2 |

63.5 |

93 |

7.4 |

|

75 |

3 |

76.2 |

105 |

8.5 |

|

100 |

4 |

101.6 |

138 |

11.9 |

|

125 |

5 |

127 |

166 |

19.7 |

|

150 |

6 |

152.4 |

192 |

24.4 |

OD and weight data is not guaranteed, and may be changed due to working pressure and service condition.