Ceramic sleeve lined pipe fittings applied in mining industry

About Ceramic sleeve lined pipe fittings

The big diameter ceramic sleeve is always a big problem for the ceramic tube manufacturers since it’s very difficult to control the deformation rate of the ceramic sleeve after it’s sintering .Also It will also need an advanced and big isostatic pressing machine to do this .So it will not only express the company’s production capability ,but company’s technology. Right now, our factory have owned both advantages which are wear resistant ceramic pressing facilities and technologies.

We met some difficulties of course when we manufacturing the ceramic sleeves and we handled all the problems after the efforts of our research and engineering people .Also we created a very convenient installation machine to do the ceramic sleeve installation into the pipes since the sleeve is very big and heavy .After a month working ,we finished this 20’ container 95% alumina ceramic sleeve lined pipes ,T pipes and elbows and customers are also very appreciated about our rapid reaction and big efforts in this projects applied in the mining slurry conveying system.

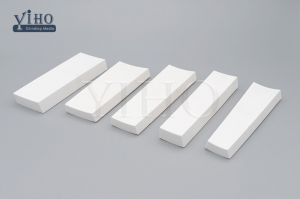

Sintering as a whole ceramic tube or ceramic sleeve,and then assemble it into the steel pipe or stainless steel pipe with our high-strength-temperature-resistant epoxy adhesive. The ceramic sleeve lined pipe has applied a lot in the mining industry ,like mining slurry pipe,mining dust removing pipe ,mining slag conveying pipe ,elbows and T pipes.

This kind of ceramic tile lined pipe consist of three parts (steel pipe + adhesive + ceramic tiles), the steel pipe is made of seamless carbon steel pipe. The ceramic tiles are 95% high alumina, and the bonding is high temperature epoxy adhesive up to 350oC.This kind of pipe are suitable for the powder transport without tile falling off or aging working under 350oC for long time. The service life span is 4 to 5 times than normal steel pipe.

Ceramic sleeve lined pipe fittings Application scope

These Pipes used for Pneumatic and Hydraulic Systems are suffering from high wear, high sliding and high impact, especially for the elbows. We can also design the custom pipe fittings to meet different working applications.

Ceramic Wear Tile Material & Photos

-92% Alumina

-95% Alumina

-99% Alumina

-RBSiC Silicon carbide

-ZTA liner

|

Category |

HC92 |

HC95 |

HCT95 |

HC99 |

HC-ZTA |

|

Al2O3 |

≥92% |

≥95% |

≥ 95% |

≥ 99% |

≥75% |

|

ZrO2 |

/ |

/ |

/ |

/ |

≥21% |

|

Density (g/ cm3 ) |

>3.60 |

>3.65g |

>3.70 |

>3.83 |

>4.10 |

|

HV 20 |

≥950 |

≥1000 |

≥1100 |

≥1200 |

≥1350 |

|

Rock Hardness HRA |

≥82 |

≥85 |

≥88 |

≥90 |

≥90 |

|

Bending Strength MPa |

≥220 |

≥250 |

≥300 |

≥330 |

≥400 |

|

Compression strength MPa |

≥1050 |

≥1300 |

≥1600 |

≥1800 |

≥2000 |

|

Fracture Toughness (KIc MPam 1/2) |

≥3.7 |

≥3.8 |

≥4.0 |

≥4.2 |

≥4.5 |

|

Wear Volume (cm3) |

≤0.25 |

≤0.20 |

≤0.15 |

≤0.10 |

≤0.05 |