Chute ceramic Tile wear liner

Chute ceramic Tile wear liner Introduction

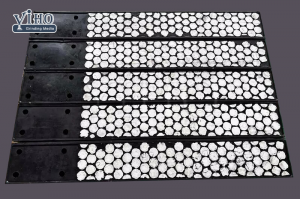

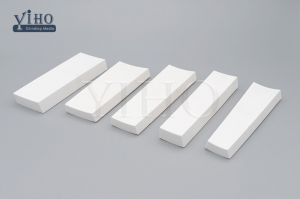

The ceramic wear liner backed steel plates are hot vulcanized together with the high tensile strength nature rubber sheet and 3~10mm steel backing plate. As a result the ceramics wear liner will have both advantages of the rubber impact resistance and ceramic wear resistance.

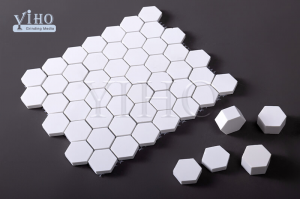

Ceramic Wear Liners can be supplied to incorporate a variety of ceramic shapes, including Rectangular tile, square time, Hexagonal Tile, cylinders and cubes.

Dimension/ Chute ceramic Tile wear liner

Yiho ceramic wear liner materials are engineered to provide superior strength, hardness, mechanical properties, and in certain applications, superior surface finishes that are key to performance and extended life. Multiple size, shape, and material configurations are available and custom solutions can be engineered for your specific application.

|

NO. |

size |

ceramic+rubber +steel |

Note |

|

1 |

500*500*50 |

28+16+6 |

Hex Tile L23.1xT28 |

|

2 |

300*300*63 |

50+7+6 |

147*97*50 |

|

3 |

300*300*35 |

25+4+6 |

147*97*25 |

|

4 |

298*298*63 |

50+7+6 |

147*97*50 |

|

5 |

190*390*25 |

15+4+6 |

Hex Tile L12.5xT15 |

|

6 |

500*500*20 |

13+1+6 |

20*20*13 |

|

7 |

450*400*63 |

50+7+6 |

147*97*50 |

|

8 |

400*300*63 |

50+7+6 |

147*97*50 |

|

9 |

450*300*63 |

50+7+6 |

147*97*50 |

|

10 |

300*200*37 |

25+6+6 |

147*97*50 |

|

11 |

300*200*37 |

25+6+6 |

147*97*50 |

|

12 |

300*150*63 |

50+7+6 |

147*97*50 |

|

13 |

500*500*50 |

30+14+6 |

47.5*47.5*30 |

|

14 |

500*500*32 |

20+6+6 |

47.5*47.5*30 |

|

15 |

500*250*32 |

20+6+6 |

47.5*47.5*30 |

|

16 |

500*500*28 |

20+2+6 |

φ20*20 |

|

17 |

500*500*50 |

40+4+6 |

φ40*40 |

|

18 |

300*300*33 |

20+7+6 |

φ20*20 |

|

19 |

390*190*63 |

40+17+6 |

φ40*40 |

|

20 |

302*302*32 |

20+6+6 |

φ20*20 |

|

21 |

500*500*32 |

20+6+6 |

φ20*20 |

|

Customized Sizes can be manufactured. |

|||

Chute ceramic Tile wear liner Feature

*Modular Bolt-In Sections

*Not Limited to Standard Sizes and Thicknesses

*Highly Customizable

*Fast Installation & Replacement

*Cost Effective

*Impact Absorbing

*Abrasion Resistant

*Noise Reduction

*Lighter Compared to Steel

Chute ceramic Tile wear liner Application

Rubber-Ceramic can be incorporated into the following applications:

*Chute Liners

* Screens

*Hoppers & Feed Box Liners – Wet & Dry Applications

*Canoe Liners

* Impact Bars

Composite Ceramic Data Sheet

|

Technical Data of the Ceramics |

|||

| Description | 92% Ceramics | 95% Ceramics | ZTA |

| Alumina Content | 92% | 95% | – |

| Density (g/cm³) | 3.65 | 3.72 | 4.2 |

| Rockwell Hardness (HRA) | 85 | 88 | 90 |

| Vickers’ Hardness (HV10) | 1200 | 1350 | 1400 |

| Fracture Toughness (KIC or MPa.√m) | 3.7 | 3.9 | 4.5 |

| Compressive Strength (MPa) | ≥ 1050 | ≥ 1300 | ≥ 2200 |

| Wear Volume (cm³) | ≤0.20 | ≤0.15 | ≤0.05 |

Technical Data of the Rubber

| Items | Index |

| Elongation | ≥ 450% |

| Tensile Strength | ≥ 180 MPa |

| Shore Hardness | 55 – 65 HA |

| Tear Strength | ≥ 70 KN/M |

| Break Permanent Deformation | ≤ 24% |

| Rubber and Ceramic Adhesion Force | ≥ 3.0 MPa |

| (Shearing Stress) | |

| Temperature Resistance | ≤ 100˚ C |

| Gap Between Tile | ≤ 2.0 mm |

| Rubber Edge | ≤ 2.0 mm |