Direct Manufacturer of 92% and 95% Al2O3 ceramic lining ball mill brick

Liner Alumina Ceramic

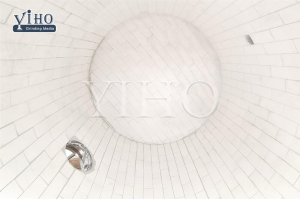

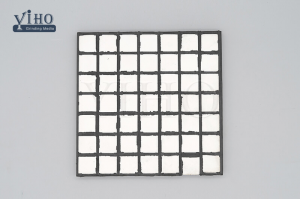

Yiho uses high quality, fine-grain 92% / 95% alumina brick with tongue and groove design. Bricks are secured and grouted with pure Portland cement or two-part epoxy. When it is time to reline a mill that is also a good time to check the bearings and drives components.

Alumina Ceramic Ball Mill Lining Application

The alumina lining bricks are used as the lining in the ball mill of ceramic industry, insulator industry. Using this liner will effectively improve grinding efficiency, reduce grinding cost, and it is considered to be your best choice.

Alumina Liner for Batch Mill and Continuous Mill: Standard thickness 40 to 90 mm. with Al2O2 content 92 to 95%.

Industry : Ceramic & Insulator

Specification of Ball Mill Brick

|

Name |

Length (mm) |

Width 1 (mm) |

Width 2 (mm) |

Thickness (mm) |

|

|

40~90mm Thickness Lining Brick |

Rectangular Brick |

150±2 |

50±1 |

50±1 |

40/50/60/70/77/90±1 |

|

Trapezoidal Brick |

150±2 |

50±1 |

45±1 |

40/50/60/70/77/90±1 |

|

|

Half Rectangular Brick |

75±1 |

50±1 |

50±1 |

40/50/60/70/77/90±1 |

|

|

Half Trapezoidal Brick |

75±1 |

50±1 |

45±1 |

40/50/60/70/77/90±1 |

|

|

Flake Brick |

150±2 |

25±1 |

22.5±1 |

40/50/60/70/77/90±1 |

|

|

Special Specification Lining Bricks |

80x50x55 |

55±2 |

50±1 |

50±1 |

80±1 |

|

110mm Ling Brick |

75±1 |

45±1 |

41±1 |

110±2 |

|

|

110mm Half Ling Brick |

37.5±1 |

45±1 |

41±1 |

110±2 |

|

|

Brick for Manhole and Drain-hole |

The specification can make according to the customers' requirements. |

||||

Alumina Ceramic Lining APPLICATION

| WEAR RESISTANT CERAMIC BRICK | |

| Alumina brick is used to reduce wear in a variety of applications in the following industries: | |

| Coal Fired Power Generation

Some of the most demanding processes require the most advanced wear resistant Alumina ceramics available. YIHO's Alumina formulations are specifically designed to provide the highest protection in these extreme wear environments. Service life of areas using YIHO's high alumina can be increase by as much as 10 times.

Mining & Mineral Processing In the mining and processing of silica sand, coal, iron ore and precious metal wear rates can be extremely high. Using Bitossi's proprietary DURALBIT you can extend the service life of equipment and reduce downtime by installing ceramic at high wear areas. We can offer a variety of sizes and shapes of ceramic, ceramic panels, hex-tiles, and custom shapes.

Grain Handling In storage and transfer stations around the world ceramic wear resistant linings have been installed to reduce the wear caused by the high speed movement of corn, rice, wheat, soybeans, and coffee. Our experts can tell how to best achieve the maximum efficiency using ceramic wear resistant linings. Pulp & Paper Processing YIHO's fine grain 92%/95% Alumina Ceramic is an ideal material that protects many areas in the pulp and paper manufacturing process. Alumina Ceramic provides a corrosion and wear resistant surface that will not contaminate the chemical solutions used in paper making. Iron & Steel Making Alumina ceramics is an ideal material tor lining skip cars, chutes, hoppers, fan housings, piping and feeder pipes. |