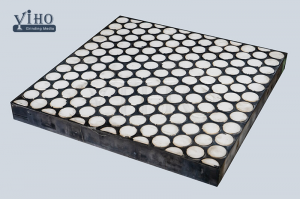

Engineering Wear Ceramic Matrix

About Wear Ceramic Matrix

Abrasion is always unavoidable in the processing and transport of bulk materials. The falling material flow causes particularly strong impact. We offer our customers best solutions with the high-quality ceramic wear matrix(with/without steel plate and bolt), in order to achieve an optimal result in increasing the impact resistance and reducing the abrasion and noise.

Ceramic Conveyor Wear Liners will substantially reduce your operating costs when compared to any other lining material.

Yiho manufactures a variety of conveyor wear liners in may options and sizes to choose from. Designed to handle any tough hard rock mining application. Abrasion resistant, modular, high-wear material to line belts chutes, and bin impact areas.

Wear Ceramic Matrix Features

* Extremely high impact resistance

* Low friction coefficients

*Noise reduction

* easy and fast montage

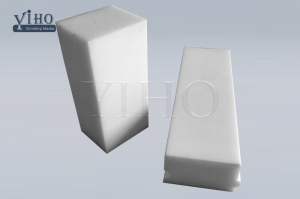

Type of Ceramics

Cylinder | Hex Tile | Rectangular |Square | Cube

92%, 95%, 99% Al2O3, ZTA, RBSIC Silicon Carbide

Technical Data:

|

Category |

HC92 |

HC95 |

HCT95 |

HC99 |

HC-ZTA |

|

Al2O3 |

≥92% |

≥95% |

≥ 95% |

≥ 99% |

≥75% |

|

ZrO2 |

/ |

/ |

/ |

/ |

≥21% |

|

Density (g/ cm3 ) |

>3.60 |

>3.65g |

>3.70 |

>3.83 |

>4.10 |

|

HV 20 |

≥950 |

≥1000 |

≥1100 |

≥1200 |

≥1350 |

|

Rock Hardness HRA |

≥82 |

≥85 |

≥88 |

≥90 |

≥90 |

|

Bending Strength MPa |

≥220 |

≥250 |

≥300 |

≥330 |

≥400 |

|

Compression strength MPa |

≥1050 |

≥1300 |

≥1600 |

≥1800 |

≥2000 |

|

Fracture Toughness (KIc MPam 1/2) |

≥3.7 |

≥3.8 |

≥4.0 |

≥4.2 |

≥4.5 |

|

Wear Volume (cm3) |

≤0.25 |

≤0.20 |

≤0.15 |

≤0.10 |

≤0.05 |

Type of Wear Matrix

* Rubber backed ceramic matrix

* Steel backed rubber ceramic matrix

Dimension of Ceramic Wear Matrix

Regular&Customized,

Max L800*W800mm

Industries Include for Ceramic Wear Matrix

• Aggregate

• Asphalt

• Cement

• Chemical

• Coal Fired

• Power

• Coal

• Processing

• Dredging

• Fertilizer

• Fiberglass

• Fly Ash

• Food

• Processing

• Foundry

• Frac Sand

• Glass & Frit

• Grain

• Gypsum

• Iron & Steel

• Mineral

• Processing

• Mining

• Oil Sands

• Oil & Gas

• Petrochemical

• Potash

• Pulp & Paper

• Quarry

• Recycling

• Roofing

• Materials

• Sand & Gravel

• Sugar

• Wastewater

• Powder/Bulk Material

• Handling

• Markets Served

• Availabl

Applications of Ceramic Wear Matrix

• Ash Slurry Lines

• Ball Mine Liners

• Bark Feed Screws

• Bark Handling Chutes

• Box Back Elbows

• Clinker Hoppers

• Coal Troughs

• Conveyor Transitions

• Cyclones

• Draft Liners

• Dust Collector Liners

• Exhaust Fan

• Housings

• Exit Ducts

• Feed Chutes

• Flat Back Elbows

• Gas Scrubber Lines

• Hog Fuel Handling

• I.D. Fan Housings

• Mill Body Housings

• Ore Bunkers

• Pulverizer Bodies

• Pulverizer Classifier

• Cones

• Pulverizer Discharge

• Valves

• Rock Bed Wall Liners

• Silos & Bunkers

• Transitions

• Truck and Rail Car

• Coal Dumps

• Washer Boxes

• Wennberg Screws