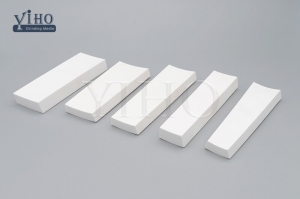

HEAVY DUTY SKIRT LINERS (CERAMIC CANOE/Skirt LINERS)

Canoe Skirt Liners are highly effective for sealing inside the skirtboard, controls the material until it becomes stable and protecting the skirt wall from wearing.

Yiho Ceamic Canoe Liner Advantages

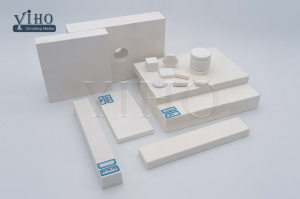

YIHO has been manufacturing wear liners of all types for over 25years. From Bolt on to weld in, canoe liners or skirting liners, with steel back or ceramic face we can supply all your requirements.

YIHO manufacture impact and wear resistant liners in almost any size and shape from the highest quality materials specifically chosen for your environment. We can work with your drawings to assist with liner layout and tag each liner for installation to the layout drawing. We can help you map out your wear lining requirements for any size or configuration.

It's worth noting that while ceramic canoe liners can offer benefits in terms of protection and durability, they may also come with some considerations:

• Bevelled edge design – insures optimum sealing inside the skirtboard to prevent material spillage

• Adjustability – of the Canoe / Skirt Liners aid in the conformity of the conveyor belt and maximize liner life

• Longer wear life – Single edge bevel or dual edge bevel for reversible wear life

• Cost: Canoe liners made from ceramic materials can be more expensive than other types of liners or coatings.

• Weight: While the weight of ceramic liners might be relatively low compared to other materials, it's still important to consider any potential impact on the overall weight and performance of the canoe.

Lining Materials- Ceramic Alumina Tile Technical Data

|

Category |

HC92 |

HC95 |

HCT95 |

HC99 |

HC-ZTA |

ZrO2 |

|

Al2O3 |

≥92% |

≥95% |

≥ 95% |

≥ 99% |

≥75% |

/ |

|

ZrO2 |

/ |

/ |

/ |

/ |

≥21% |

≥95% |

|

Density (g/ cm3 ) |

>3.60 |

>3.65g |

>3.70 |

>3.83 |

>4.10 |

>5.90 |

|

HV 20 |

≥950 |

≥1000 |

≥1100 |

≥1200 |

≥1350 |

≥1100 |

|

Rock Hardness HRA |

≥82 |

≥85 |

≥88 |

≥90 |

≥90 |

≥88 |

|

Bending Strength MPa |

≥220 |

≥250 |

≥300 |

≥330 |

≥400 |

≥800 |

|

Compression strength MPa |

≥1050 |

≥1300 |

≥1600 |

≥1800 |

≥2000 |

/ |

|

Fracture Toughness (KIc MPam 1/2) |

≥3.7 |

≥3.8 |

≥4.0 |

≥4.2 |

≥4.5 |

≥7.0 |

|

Wear Volume (cm3) |

≤0.25 |

≤0.20 |

≤0.15 |

≤0.10 |

≤0.05 |

≤0.02 |

Yiho Ceramic Products Ranges

Ceramic Grinding Media

*. 92% alumina grinding ball, 95% alumina grinding ball, 99% alumina grinding balls

*. silicate zirconia grinding ball

*. ZTA(zirconia toughened alumina) grinding ball including ZTA 370, ZTA380 and so on.

*. yttria zirconia grinding ball, ceria zirconia grinding ball

Ceramic Wear Lining

*. Alumina ceramic mosaic tile(shape: square, hex..)

*. Alumina ceramic brick (the thickness is from 25mm to 90mm)

*. Alumina ceramic plate

*. Weldable ceramic lining

*. Rubber backed ceramic mat, steel backed rubber ceramic mat

*. Ceramic tubes, Elbows, Ceramic lined Steel pipes and elbows

* .ZTA tiles