HEAVY WEAR PROTECTION Ceramic Rubber Liner Materials

Ceramic Rubber Liner Introduction

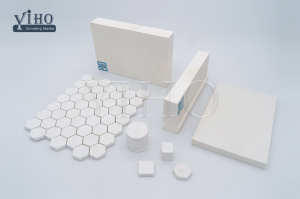

Yiho offers a number of custom wear-resistant rubber-ceramic liner solutions that provide long-term protection for Mining equipment.

Our liners will combat impact, abrasion, noise, and sticking, providing superior protection in the most severe conditions. Custom liners can be designed to suit any application. Based on your needs,

liners can be installed by welding, bolting, or with high-strength magnets.

Ceramic rubber liner can be produced in different sizes and configuration to suit different chute sizes or requirements. Bonding layer backed ceramic wear liner can be bonded to equipment directly. Ceramic rubber liner offers much better wear performance than rubber wear plate and steel plate, and ceramic wear plates can be produced with numerous fixing methods.

Ceramic Materials

92 %, 95%, 99% -Al2O3 ceramic tiles (Cylinder, square, rectangular or

hexagonal „SW“) vulcanized in special rubber with CN bonding layer.

|

Al2O3 |

SiO2 |

CaO |

MgO |

Na2O |

|||

|

92%~99% |

3~6% |

1~1.6% |

0.2~0.8% |

0.1% |

|||

| Specific gravity (g/cc) |

>3.60 |

>3.65 |

>3.70 |

||||

| Apparent porosity (%) |

0 |

0 |

0 |

||||

| Bending Strength (20℃, Mpa) |

220 |

250 |

300 |

||||

| Compressive strength (20℃, Mpa) |

1050 |

1300 |

1600 |

||||

| Rockwell hardness (HRA) |

82 |

85 |

88 |

||||

| Vickers hardness (HV20) |

1050 |

1150 |

1200 |

||||

| Moh’s hardness (scale) |

≥9 |

≥9 |

≥9 |

||||

| Thermal Expansion (20-800℃, x10-6/℃) |

8 |

8 |

8 |

||||

| Abrasion Loss (Cm3) |

0.25 |

0.2 |

0.15 |

||||

Ceramic Cylinder Sizes (92%, 95%, 99% Al2O3 Content)

|

20x20mm |

20x25mm |

|

30x30mm |

30x20mm |

|

40x40mm |

40x20mm |

|

50x50mm |

50x25mm |

Ceramic Rubber Liner Properties

• CN bonding layer provides fast and long lasting adhesion

• Highest abrasion resistance

• Reduces operating costs

• Long service life increases the efficiency of the equipment

• Good resistance against weather

Area of application of Ceramic Rubber Liner

• Lining against extreme wear through abrasion at high speeds

• For simple to medium duty applications in mining, gravel, sand and stone breaking mills and other industrial sectors

• In applications like pipelines, vibratory feeders, cyclones, skips, bunkers, chutes, loading points, slides, hoppers, silos