HEAVY WEAR PROTECTION Ceramic/rubber lining material

Ceramic/rubber lining material

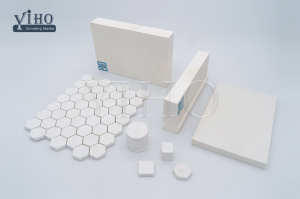

Ceramic composite rubber lining backed steel plate is the liner vulcanizing the ceramic and rubber into the steel plate. It can be connect with bolts and nuts or by welding the steel plate to do the connections. This product is normally the customized products, it can be made with different shapes, different thickness according to the working conditions.

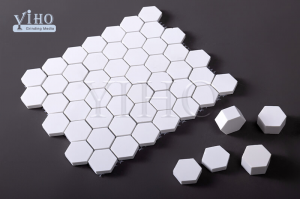

The liner is a composite construction of highly wear-resistant 92 %-Al2O3 ceramic tiles (square, rectangular or hexagonal „SW“) vulcanized in special rubber with CN bonding layer.

Properties

• CN bonding layer provides fast and longlasting adhesion

• Highest abrasion resistance

• Reduces operating costs

• Long service life increases the efficiency of your equipment

• Good resistance against weather

Area of application

• Lining against extreme wear through abrasion at high speeds

• For simple to medium duty applications in mining, gravel, sand and stone breaking mills and other industrial sectors

• In applications like pipelines, vibratory feeders, cyclones, skips, bunkers, chutes, loading points, slides, hoppers, silos

Specifications

|

Polymer basis |

NR/BR/SBR |

DIN ISO 1629 |

|

Specific weight |

1.12 g/cm³ |

DIN EN ISO 1183-1 |

|

Hardness |

62 Shore A |

DIN ISO 7619-1 |

|

Colour |

Black |

|

|

Ref. No. |

Designation |

Dimensions |

Dimensions of ceramic tiles |

Weight |

|

539 9022 |

10/4 |

14 x 500 x 500 mm |

10 x 20 x 20 mm |

10 kg |

|

539 9039 |

25/15 |

40 x 500 x 600 mm |

25 x 100 x 150 mm |

32 kg |

|

539 9046 |

HEX 6/6 |

12 x 510 x 525 mm |

SW 32 x 6 mm |

Applicable Scope Of Ceramic Rubber Lining

This product used as wear resistant lining in the equipment working at strong impact and serious abrasion.

The working temperature of this product is -50℃ to 350℃

Characters Of Ceramic Rubber Lining

* The Ceramic rubber wear plate is good for both sliding and impact abrasion, and its extremely good for high impact application.

* The Ceramic rubber wear plate can be installed either by glue or by screw-bolt system, its much higher installation efficiency than alumina ceramics, and the shutdown time can be reduce, therefore, it will help to reduce the loss due to exchange the liner.

* Due to the elasticity of the rubber, the ceramic rubber wear plate has less sound when the material pass, therefore, its an environmental friendly products.