High alumina Weld-on wearing tiles

High Alumina Weld-on Wearing Tiles Introduction

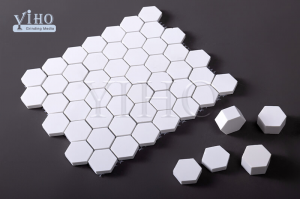

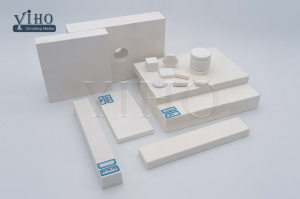

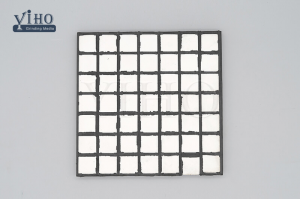

Ceramic tiles have excellent abrasion and wear resistant qualities and are ideal for use in transfer chutes, piping systems, hoppers, etc. Typical markets include grain, coal-fired power generation, mining, cement, and more.

YIHO Manufactures a full range of high-density, fine-grain, wear-resistant alumina ceramic wear tiles to prevent erosion and abrasion in conveying and bulk material handling systems. Our alumina ceramic is next to diamond in hardness, is 12 times more wear-resistant than carbon steel, and exhibits excellent corrosion resistance.

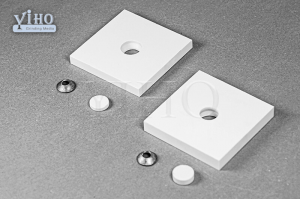

Weldable tiles are provided with a hole though the tile, a carbon steel weld cup, and a ceramic plug for welding in pace onto a steel substrate.

Available in purity ranges from 92% to 99% for the most demanding applications.

High Alumina Weld-on Wearing Tiles Standard Dimensions

|

Length |

Widt |

Thickness |

|

50 |

50 |

15 |

|

50 |

50 |

17 |

|

50 |

50 |

20 |

|

60 |

20 |

35 |

|

60 |

40 |

10 |

|

70 |

70 |

10 |

|

70 |

70 |

15 |

|

75 |

75 |

20 |

|

75 |

75 |

25 |

|

75 |

75 |

30 |

|

75 |

75 |

35 |

|

100 |

50 |

8 |

|

100 |

50 |

12 |

|

100 |

50 |

12.5 |

|

100 |

50 |

15 |

|

100 |

50 |

20 |

|

100 |

50 |

25 |

|

100 |

75 |

12 |

|

100 |

75 |

20 |

|

100 |

75 |

25 |

|

100 |

75 |

30 |

|

100 |

100 |

10 |

|

100 |

100 |

12 |

|

100 |

100 |

15 |

|

100 |

100 |

20 |

|

100 |

100 |

25 |

|

100 |

100 |

30 |

|

100 |

100 |

35 |

|

100 |

100 |

40 |

|

100 |

100 |

45 |

|

120 |

80 |

8 |

|

120 |

80 |

10 |

|

120 |

80 |

12 |

|

120 |

80 |

14 |

|

120 |

80 |

15 |

|

120 |

80 |

20 |

|

120 |

80 |

25 |

|

120 |

80 |

30 |

|

150 |

50 |

10 |

|

150 |

50 |

12 |

|

150 |

50 |

12.7 |

|

150 |

50 |

15 |

|

150 |

50 |

20 |

|

150 |

50 |

25 |

|

150 |

50 |

30 |

|

150 |

50 |

35 |

|

150 |

50 |

40 |

|

150 |

50 |

50 |

|

150 |

100 |

10 |

|

150 |

100 |

12 |

|

150 |

100 |

14 |

|

150 |

100 |

15 |

|

150 |

100 |

20 |

|

150 |

100 |

23.5 |

|

150 |

100 |

24 |

|

150 |

100 |

25 |

|

150 |

100 |

30 |

|

150 |

100 |

40 |

|

150 |

100 |

50 |

|

150 |

100 |

70 |

High Alumina Weld-on Wearing Tiles Technical Data

|

Category |

HC92 |

HC95 |

HCT95 |

HC99 |

|

Al2O3 |

≥92% |

≥95% |

≥ 95% |

≥ 99% |

|

ZrO2 |

/ |

/ |

/ |

/ |

|

Density (g/ cm3 ) |

>3.60 |

>3.65g |

>3.70 |

>3.83 |

|

HV 20 |

≥950 |

≥1000 |

≥1100 |

≥1200 |

|

Rock Hardness HRA |

≥82 |

≥85 |

≥88 |

≥90 |

|

Bending Strength MPa |

≥220 |

≥250 |

≥300 |

≥330 |

|

Compression strength MPa |

≥1050 |

≥1300 |

≥1600 |

≥1800 |

|

Fracture Toughness (KIc MPam 1/2) |

≥3.7 |

≥3.8 |

≥4.0 |

≥4.2 |

|

Wear Volume (cm3) |

≤0.25 |

≤0.20 |

≤0.15 |

≤0.10 |

Called “the material of the future”, alumina ceramics is one of the hardest of all natural substances. Even under extremely abrasive conditions, no material can compete with its extreme hardness and wear resistance. It has exceptional chemical, mechanical, thermal and electrical insulation properties and can be formed into any shape or size with various qualities for specific applications.