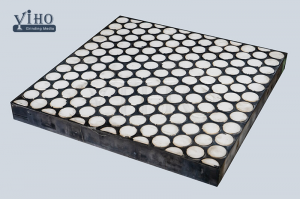

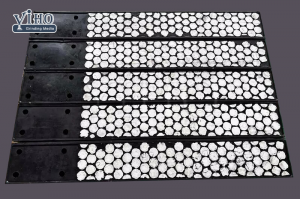

High Durability Customized Ceramic Wear Tiles for Increased wear resistance

YIHO offers a full range of shapes and sized ceramic tiles for your severe wear lining applications. YIHO can offer standard sized tiles (square and rectangular), hex tiles as well as custom shapes and sizes for your demanding application.

YIHO offers a complete material portfolio for these ceramic wear tiles including; several grades of Aluminum Oxide 92%, 95%, 99%, Zirconia Toughened Alumina(ZTA), Zirconia, Reaction Bonded Silicon Carbide as well as Sintered Silicon Carbide for your most extreme corrosion, abrasive and wear environments.

Pre-engineered alumina tiles are tailor made to suit any type of application such as short and long radius bends, small and large bore pipe sections, square to round transitions, cones, pipe junctions and connections etc. The ceramic wear tiles, when installed correctly, provide some resistance to low levels of shock and extreme sliding abrasion, caused by material passing over and wearing the surface of the part.

Ceramic Wear Tiles Application Area

- Classifiers and cones

- Fan impellers and casings

- Cyclone separator shells/Parts

- Hoppers and Chutes

- Tubes, pipes, Bends and Elbows

Ceramic Wear Tiles Specifications

|

Category |

HC92 |

HC95 |

HCT95 |

HC99 |

HC-ZTA |

ZrO2 |

|

Al2O3 |

≥92% |

≥95% |

≥ 95% |

≥ 99% |

≥75% |

/ |

|

ZrO2 |

/ |

/ |

/ |

/ |

≥21% |

≥95% |

|

Density (g/ cm3 ) |

>3.60 |

>3.65g |

>3.70 |

>3.83 |

>4.10 |

>5.90 |

|

HV 20 |

≥950 |

≥1000 |

≥1100 |

≥1200 |

≥1350 |

≥1100 |

|

Rock Hardness HRA |

≥82 |

≥85 |

≥88 |

≥90 |

≥90 |

≥88 |

|

Bending Strength MPa |

≥220 |

≥250 |

≥300 |

≥330 |

≥400 |

≥800 |

|

Compression strength MPa |

≥1050 |

≥1300 |

≥1600 |

≥1800 |

≥2000 |

/ |

|

Fracture Toughness (KIc MPam 1/2) |

≥3.7 |

≥3.8 |

≥4.0 |

≥4.2 |

≥4.5 |

≥7.0 |

|

Wear Volume (cm3) |

≤0.25 |

≤0.20 |

≤0.15 |

≤0.10 |

≤0.05 |

≤0.02 |

Ceramic Wear Tiles Specifications

Please contact us and allow our application engineers the opportunity to work with your engineering team to recommend the right advanced ceramic materials for your toughest challenges.