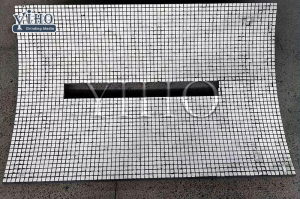

Hot Vulcanization Rubber Ceramic Composite Wear Panels

Hot Vulcanization Rubber Ceramic Composite Wear Panels Introduction

YIHO Wear Panel solutions are ideal for a wide variety of mining, mineral processing and material handling for protection against extreme wear.

A. Ceramic and rubber vulcanization process mature and reliable.

In the ceramic surface treatment before vulcanization, we use the US imports of surface treatment agent. Vulcanized products Even if the liner is bent 360 °, the ceramic will not fall off the rubber.

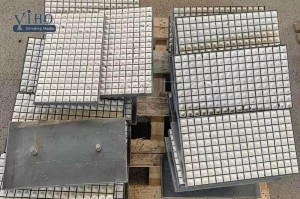

B. ceramic liner and steel paste firmly

In the ceramic liner and steel bonding, we use imported metal and rubber adhesive. The product has strong adhesion, good heat resistance, acid and alkali resistance, corrosion resistance, anti-aging and so on. As my company's ceramic rubber liner paste special adhesive, nearly a decade in the use of hundreds of customers, reliability is very good, so far, no one product off the problem.

Organic adhesive maximum temperature of 100 ℃, the lowest minus 50 ℃. Mainly applicable to the ceramic rubber composite liner paste, due to strong adhesion of organic viscose, while the liner and equipment contact area is large, very suitable for large impact, serious wear and tear of the material conveying system, such as power plant coal handling system, Steel, smelting sintering plant and so on.

Hot Vulcanization Rubber Ceramic Composite Wear Panels Application

Typical application examples:

· Chutes

· Cyclones

· Launders

· Pipes and tanks

· Conveyor transfer points

· Screen beams, underpans and components

· Vibratory feeders

Hot Vulcanization Rubber Ceramic Composite Wear Panels Key features and benefits

Key features and benefits

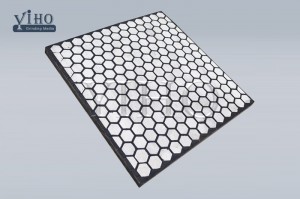

• 92% Aluminium oxide material.

• Rubber compound blended with CN polymers.

• Buffed CN bonding layer and buffed edges.

• Manageable size and weight. Strip width 250mm makes it easy to install.

• Fire resistant and antistatic (FRAS) rubber compound available.

• Low sulphur rubber.

• Ceramic tiles bonded to rubber on all sides (except top surface).

• Supplied in square panels 500mm x 500mm.

• Extreme wear resistance.

• Outstanding adhesion to ceramic tiles, rubber and metal.

• For optimum cold vulcanised adhesion.

• Can be used in above and below ground applications.

• Stable rubber hardness with age.

• Resists tile cracking and pull out.

• Easy to install.

Rubber,Ceramic&Steel Specification

|

S.No. |

Material |

Attributes |

Properties |

|

1 |

Ceramic Tiles |

Material |

92%, 95%, T95%,99%, ZTA |

|

2 |

Rubber |

Component |

Natural rubber |

|

Density |

1.4g/cm3 |

||

|

Tensile strength at break |

≥10.6Mpa |

||

|

Elongation at break |

≥350% |

||

|

Shore Hardness |

45-65 |

||

|

Adhesive between tile and rubber |

≥3.8 Mpa |

||

|

Adhesive between rubber and equipment |

≥3.58Mpa |

||

|

Thermal conductivity.(normal temperature) |

2w/m·k |

||

|

Aging period |

≥15 Years |

||

|

Working temperature |

-50ºC - 200ºC |

||

|

3 |

Steel plate |

Material |

Q235A |

|

Density |

7.85g/cm3 |

||

|

Thickness |

3-10mm |

||

|

4 |

Adhesive |

Appearance |

Brown glutinous liquid |

|

Solid content |

20±3% |

||

|

Viscosity |

≥2.5 Mpa |

||

|

Peel strength |

48h N/2.5cm≥120 |

||

|

Compressive strength |

≥850 Mpa |

||

|

Working temperature |

-20ºC - 100ºC |