Impact & Abrasion Resistance Rubber Backed Ceramic Liner

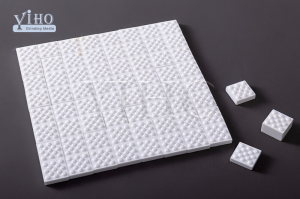

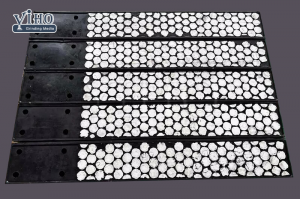

Alumina ceramic lining plate is a high abrasion-resistant wear product, it is a combination of high alumina ceramic tiles and natural rubber.

High alumina ceramic lining offers wear protection and can extend service life of chute or other equipment significantly, wear life of high alumina ceramic is approx. 5 timers longer than rubber and 10 times longer than steel.

Alumina Ceramic Benefits

* Superior wear resistance of high alumina ceramics.

* Energy-absorbing rubber cushions, more impact resistant.

* Extend wear life of your production line, reduce maintenance and downtime.

The rubber backed ceramic liners have superior wear resistance. Liners comprising of high alumina ceramics and energy-absorbing rubber cushions which are more impact resistant. These features will also extend the wear life of your production line, and reduce maintenance and downtime. Rubber Backed Ceramic Liners can be supplied in both with CN Bonding Layer and buff back. Liner with bonding layer can be bonded to parent metal directly by adhesive.

The liners can be customized depending on the application.

Installation of Rubber backed Ceramic Liner

1. Rubber ceramic lining produced with or without steel plate and stud

-fixed to steel plate by studs, nuts and washers.

2. Ceramic lining with CN bonding layer.

-be bonded to steel plate by adhesive.

3. Alumina ceramic lining can also be produced with steel or aluminum channel -fixed by studs

|

Number |

Style |

Length (mm) |

Width (mm) |

Thickness (mm) |

Ceramic Size(mm) |

|

1 |

Rubber Backed Ceramic Panel |

300 |

300 |

10 |

17.5*17.5*6 |

|

2 |

291 |

288 |

18.5 |

hexogan 12.5*12.5 |

|

|

3 |

300 |

300 |

8 |

17.5*17.5*4 |

|

|

4 |

500 |

250 |

95 |

150*47*50 |

|

|

5 |

508 |

508 |

30 |

hexogan 23.1*25 |

|

|

6 |

305 |

305 |

30 |

hexogan 23.1*25 |

|

|

7 |

500 |

500 |

10 |

17.5*17.5*6 |

|

|

8 |

500 |

500 |

20 |

17.5*17.5*15 |

|

|

9 |

500 |

500 |

30 |

48.5*48.5*25 |

|

|

10 |

500 |

500 |

28 |

Ø20*20 |

|

|

11 |

500 |

500 |

50 |

Ø40*40 |

|

|

12 |

500 |

500 |

20 |

Ø20*15 |

|

|

13 |

500 |

250 |

20 |

Ø20*15 |

|

|

14 |

300 |

300 |

20 |

Ø20*15 |

|

|

15 |

500 |

500 |

30 |

Ø20*25 |

|

|

16 |

500 |

250 |

30 |

Ø20*25 |

|

|

17 |

300 |

300 |

30 |

Ø20*25 |

|

|

18 |

Ceramic-Rubber-Steel Panel |

300 |

300 |

35 |

146*97*25 |

|

19 |

300 |

300 |

63 |

146*97*50 |

|

|

20 |

240 |

240 |

32 |

45*45*20 |

|

|

21 |

482 |

457 |

76 |

150*100*50 |

|

|

22 |

300 |

300 |

33 |

Ø20*20 |

|

|

23 |

390 |

190 |

63 |

Ø40*40 |

|

|

24 |

415 |

240 |

32 |

Ø20*20 |

|

|

25 |

444 |

292 |

32 |

Ø20*20 |

|

|

26 |

302 |

302 |

32 |

Ø20*20 |

|

|

27 |

500 |

500 |

32 |

Ø20*20 |

Rubber backed Ceramic Liner Benefits

• Exceptional wear life and performance.

• Reduced downtime and maintenance cost.

• Outstanding operating performance.

Rubber Backed Ceramic Liner Application

• Dredging

• Mining

• Cement

• Steel

• Power plants