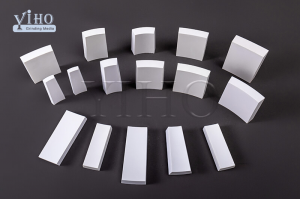

Monolithic Silicon Carbide Cyclone and Hydrocyclone Liners

Polyurethane Encased Hydrocyclone Liners

YIHO turn-key solution for hydrocyclone slurry separators and other mineral processing equipment delivers single-sourced, completed encapsulated assemblies in just weeks. Where required, our proprietary silicon carbide based formulations can be cast into complex shapes and then encased in polyurethane in-house, providing ease of installation, crack mitigation and added wear insurance, all while delivering a complete solution from one vendor. The VERKAPSE process reduces both cost and lead time for customers while providing a product with greater overall durability and reliability.

All proprietary silicon carbide based materials can be cast into very complex shapes, displaying tight and repeatable tolerances that ensure repeated ease of installation. Expect a more abrasion resistant product than cast steels, rubber and urethanes alone at one-third the weight of their steel counterparts. All offer much higher thermal and corrosion resistance.

YIHO also produces monolithic drop-in replaceable silicon carbide cyclone and hydrocyclone liners specifically engineered for separating and classifying applications. These ceramic liners are designed for highly abrasive ores including coal, iron, gold, copper, cement, phosphate mining, pulp & paper and wet FGD and are available in sizes up to 60″ in diameter.

A variety of highly abrasion resistant ceramic compositions are available, maximizing cyclone life and eliminating high installation costs traditionally found in epoxied tile constructions. This assists both OEMs and single plants in achieving financial performance objectives by optimizing classification efficiencies.

YIHO supplies either the complete assembly of the hydrocylone or the high wear areas including the bottom apex and spigots. Cones, cylinders, vortex finders and volute feed inlet heads are precision cast for repeatable assembly into your existing hydrocyclone.

Technical Data of Silicon Carbide + Polyurethane

|

Polyurethane Data |

|||

|

Specific Density 1 |

1.3kg/L |

Tear Strength |

40-100KN/m |

|

Shore A Hardness |

35-95 |

Tensile Strength |

30-50MPa |

|

Akron abrasion |

<0.053(CM3/1.61km) |

Deformation |

<8% |

|

Working Temperature |

-25-80℃ |

Insulation Strength |

Excellent |

|

Expansion strength |

70KN/m |

Grease resistant |

Excellent |

| Silicon Carbide Data(RBSiC) | ||

|

Index |

Value |

Test result |

|

Sic |

/ |

≧90 |

|

Temperature |

℃ |

1380 |

|

Specific Density |

g/cm3 |

≧3.02 |

|

Open Porosity |

% |

<0.1 |

|

Modulus of elasticity: |

Gpa |

330Gpa (20℃) 300Gpa(1200℃) |

|

Moh’s Hardness |

/ |

9.6 |

|

Bending strength |

Mpa |

250(20℃)/ 280 (1200℃) |

|

Compression Strength |

Mpa |

1150 |

|

Coefficient of thermal expansion: |

/ |

4.5K^(-3)*10^(-5) |

|

Coefficient of thermal conductivity: |

W/m.k |

45 (1200℃) |

|

Acid Alkaline -proof |

/ |

Excellent |