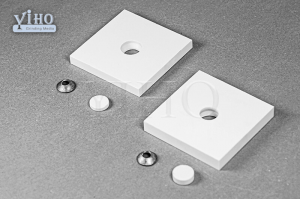

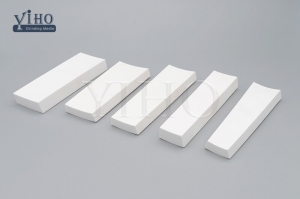

Polyurethane structural parts For Wear Resistant Use

Polyurethane structural parts are widely used in wear-resistant applications due to their unique combination of properties that make them suitable for various industries and environments. When used as wear-resistant components.

Polyurethane offers several advantages

1 Abrasion Resistance: Polyurethane exhibits excellent resistance to abrasion and wear, making it ideal for applications where components are subjected to sliding, impact, or abrasive wear.

2 Toughness and Flexibility: Polyurethane is known for its toughness and flexibility, allowing it to withstand repeated mechanical stresses and deformation without cracking or breaking.

3 Impact Resistance: Polyurethane structural parts can absorb and dissipate energy from impacts, protecting the underlying surfaces and extending the lifespan of the equipment or machinery.

4 Chemical Resistance: Depending on the specific formulation, polyurethane can be engineered to resist exposure to various chemicals, including acids, bases, oils, and solvents.

5 Water and Moisture Resistance: Polyurethane is inherently resistant to water and moisture, making it suitable for applications in wet or humid environments without significant degradation.

6 Noise and Vibration Damping: Polyurethane's elastic properties help dampen vibrations and reduce noise levels, making it beneficial for noise-sensitive applications or equipment.

7 Customizable Formulations: Polyurethane can be tailored to specific wear-resistant applications by adjusting its hardness, flexibility, and other properties during the manufacturing process.

8 Lightweight: Compared to metal alternatives, polyurethane structural parts are lightweight, making handling and installation easier and potentially reducing the overall weight of equipment.

9 Low Friction Coefficient: Polyurethane has a low coefficient of friction, reducing the risk of material build-up and improving the efficiency of sliding or moving parts.

10 Ease of Machining and Forming: Polyurethane can be easily machined and formed into various shapes, allowing for the productio

Ease of Machining and Forming: Polyurethane can be easily machined and formed into various shapes, allowing for the production of complex wear-resistant components.

Common examples of wear-resistant polyurethane structural parts include conveyor belt components, chute linings, seals, gaskets, wheels, and bushings in industries such as mining, construction, agriculture, material handling, and automotive.

It is essential to select the appropriate polyurethane formulation and design the components to suit the specific wear conditions and requirements of the application. With proper engineering and material selection, polyurethane structural parts can significantly improve the performance and durability of machinery and equipment in wear-prone environments.

Polyurethane Wear Parts Technical Data

|

Specific Density 1 |

1.3kg/L |

Tear Strength |

40-100KN/m |

|

Shore A Hardness |

35-95 |

Tensile Strength |

30-50MPa |

|

Akron abrasion |

<0.053(CM3/1.61km) |

Deformation |

<8% |

|

Working Temperature |

-25-80℃ |

Insulation Strength |

Excellent |

|

Expansion strength |

70KN/m |

Grease resistant |

Excellent |

Yiho Ceramic wear Products Lines

- Alumina Ceramic Tile linings 92~99% Alumina

- ZTA Tiles

-Silicon Carbide Brick/ Bend/ Cone /Bushing

- Basalt Pipe/Brick

-Ceramic Rubber Steel Composite products

- Monolithic Hydro Cyclone