Products

-

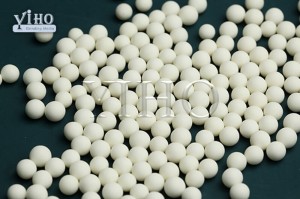

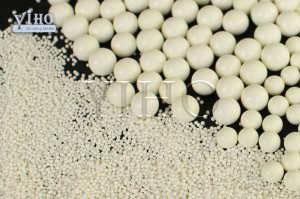

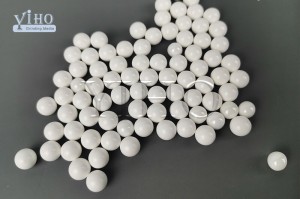

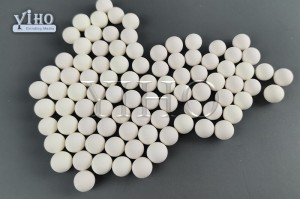

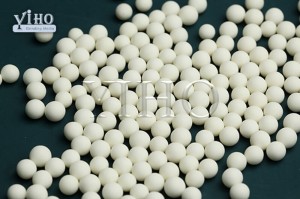

Ball mill alumina grinding media

Alumina grinding balls are widely used in ball mills as abrasive media for ceramic raw materials and glaze materials. Ceramic, cement and enamel factories as well as glasswork plants use them because of their excellence of high density, their high hardness, and their high wear resistance. During the abrasive/grinding processing, ceramic balls will rarely be broken and the contamination factor is minimal.

-

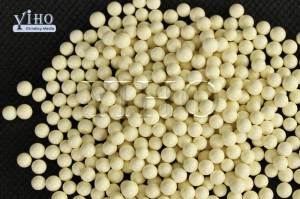

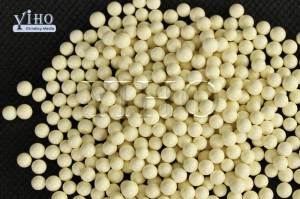

Bead mill Zirconium ball grinding media

YihoZirconium silicate beads are a type of media that is used for grinding, milling, and dispersion of materials. They have a glossy appearance with a satin-smooth finish. This media can be used in both horizontal mills well as the vertical mill. Yiho Zirconium Silicate Ball consists of 45%~50% percent of zirconia and the rest is Silicon Dioxide (SiO2) and Aluminum Oxide (Al2O3).

-

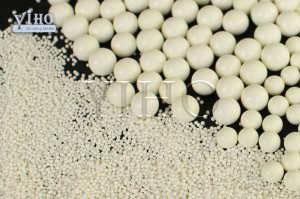

Ceramic grinding meida zirconia silicate grinding beads

Yiho Provides a comprehensive range of Ceramic Grinding Media, Including

- Alumina Grinding Ball with High Density and Medium Density -

High alumina ceramic grinding media

Alumina Grinding Media is high grade milling media produced by isostatic pressing and fired at high temperature. These feature high hardness, high density, low wear loss, good normalization, and good corrosion resistance.

-

Polyurethane grinding ball

Polyurethane ball is zero pollution medium ball which purchased by part of the specific high-tech enterprise. Our company adopts the special processing technology to ensure the concentricity of the inner metal ball and outer polyurethane lining, greatly improved its service life, and safety character. Now it is widely used in the grinding and mixing of all kinds high grade materials.

-

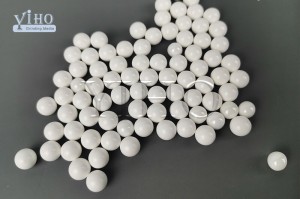

Yttria Zirconnia Grinding Ball

Yttrium Stabilized Zirconia (Y-TZP) is the strongest ceramic material we offer. Y-TZP is a purely tetragonal phase, fine grain material. This material offers the highest flexural strength of all Zirconia based materials.

-

ZTA alumina composite zirconia ceramic grinding media

ZTA (Zirconia Toughened Alumina) is a composite material made from alumina and zirconia. It combines the outstanding characteristics of both materials.

-

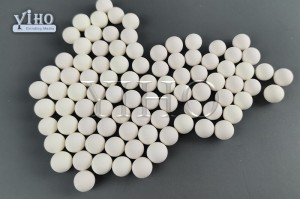

ZTA Ceramic Grinding Balls

Zirconium Toughened Alumina Grinding balls are special products which developed by Yiho R&D team after several years of research and experiments. Yiho adopt our experienced roll / granulation method for forming this type of products to make it specifically suitable for Mining wet grinding applications. Proved by many comparison wear rate tests, ZTA shows low wear loss than various quality High Alumina ( 90 – 92 % Al2O3 ) grinding media, and its similar density enables this product to to be more suitable in ultra-fine grinding fields very well.

-

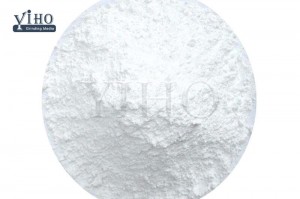

Refractory calcined aluminum oxide powder

Alumina powder is an inorganic substance with the chemical formula Al2O3. It is a high hardness compound with a melting point of 2054°C and a boiling point of 2980°C. It is an ionic crystal that can ionize at high temperature and is often used in the manufacture of refractory materials.

-

Backpack wear-resistant ceramic lined elbow-reinforced elbow

Yiho Wear-resistant ceramic lined bend adopts a special design, so that after the last piece of a circle is embedded, a 360° mechanical self-locking force is formed between the ceramic tiles to ensure a tight ceramic bonding.

-

Polyurethane milling & Grinding Jar

High wear-resistant polyurethane mill jar has an excellent performance in electronic industry and battery material.It does not bring harmful impurities into grinding materials in working process,and ensures quality of the electronic products.

-

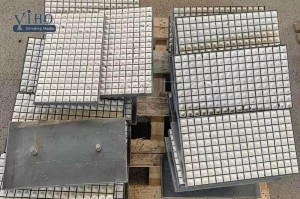

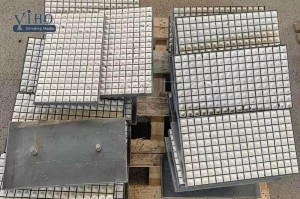

2 in1 or 3 in 1 Composite Ceramic Wear Plate

Composite ceramic rubber wear plate.

Excellent wear resistance, wear life of high alumina ceramic is approx. 5 timers longer than rubber and 10 times longer than steel.

More impact resistant, rubber or polyurethane cushions makes more impact resistant.

Available in irregular shapes and sizes.