Products

-

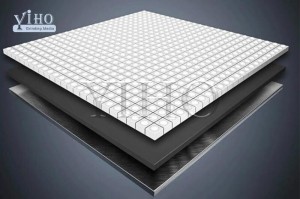

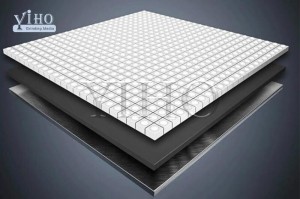

Ceramic wear plates for aggressive abrasion

Ceramic wear plate is used in truly aggressive environments where heavy flows of rough materials causes impact and strain on the equipment. Ceramic wear plate contributes to better abrasion resistance, higher payload and much longer service life.

-

RUBBER-CERAMIC WEAR LINERS

The majority of our wear liners are designed for use in the process plant, power generation and material handlings industries. Wear lining materials used include ceramic linings, ceramic composites, rubber wear plates that include ball mill liners and profile liners among many others, basalt linings, epoxy wear compounds

wear liner solutions protect your materials handling chutes, bins and tanks and improve the flow of material through your plant. Our installation teams undertake complete installation of your wear liners and provide assistance and/or supervision when required.

-

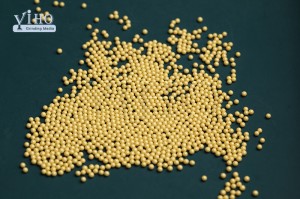

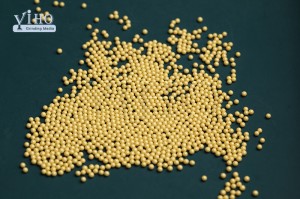

80 Cerium Stabilized Ceramic Grinding Media Balls , High Shear Sand Mill Grinding Media

Cerium stabilized zirconia ceramic grinding media beads is made of cerium stabilized zirconia powder by a process of titration molding, and baking and phasing. The microstructure of the beads is more delicate and denser, which is suitable for the dispersion and grinding of high solid content and difficult to decompose materials. It is the largest specific ceramic grinding media.

-

Agate Grinding Balls for Lab Planetary Ball Mill

Agate is a microcrystalline variety of silica, chiefly chalcedony, characterised by its fineness of grain and brightness of colour. High purity natural Brazilian agate (97.26% SiO2) grinding media balls, highly wear-resistant and resistant to acids (except HF) and solvent, these balls are used whenever small quantity of samples need to be grinded without contamination. Different sizes of agate grinding balls available: 3mm to 30mm. The grinding media balls are extensively applied to in the fields of Ceramics, Electronics, Light Industry, Medicine, Food, Geology, Chemical Engineering and so on.

-

Alumina (Al2O3) Grinding Balls

Microcrystalline abrasion-resistant alumina ball is a high-quality grinding medium, made of selected advanced materials, advanced forming technology, and calcined in a high-temperature tunnel kiln. This product has high density, high hardness, low wear, good seismic stability and good corrosion resistance. It is the most ideal medium for grinding glazes, billets and mineral powders, and is used as a grinding medium for ceramic and cement ball mills. , Coatings, refractories, inorganic mineral powder and other industries.

-

High Density Ball Mill Grinding Media Polyurethane Balls Non Toxic 15mm 20mm 30mm

Polyurethane Ball Mill Grinding Media Dimension 15-30 MM

-

Yttrium Stabilized Zirconia Milling Media

Yiho offers yttrium stabilized zirconia beads ranging from 0.1mm to40mm.

Ceria-stabilized zirconia milling media beads are also available.

-

Zirconia (YSZ) Rod cylinder grinding media

Yttria stabilized zirconia(YTZP) is a sintered advanced ceramic material and it is the most common form of stabilized zirconia ceramic. Typical composition of Yttria Stabilized Zirconia is 94.7% ZrO2 + 5.2% Y2O3(weight percentage) or 97 ZrO2 + 3% Y2O3 (mol percentage)

-

Zirconia Ceramic Rod, Shaft, Plunger

Zirconia ceramic are used in shaft , plunger, sealing structure, auto mobile Industrial, oil drilling equipment, Insulation parts in electrical equipment , ceramic knife, ceramic hair clipper spare parts, with high density, bending strength and breaking tenacity.

-

Zirconium Oxide(Zro2)Zirconia Ceramic Grinding Balls

Zirconium Oxide(Zro2)Zirconia Ceramic Grinding Balls

Yihois a leading supplier ofceramic grinding balls. We offer a selection of high-quality ceramic balls in a range of sizes including0.5 and over60 in diameter for a variety of applications.

-

92% High alumina grinding media balls

Alumina grinding media ball is mainly used in ceramic, glaze, paint, zirconia silicate, aluminum oxide, quartz, silicon carbide, talc, lime carbonate, kaolin, titanium and other materials grinding, and mechanical equipment accessories.

-

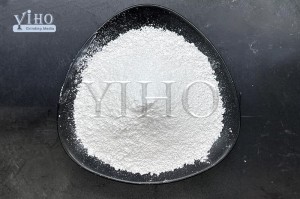

Alumina Powder/α-Alumina Micropowder

Alumina powder is an inorganic substance with the chemical formula Al2O3. It is a high hardness compound with a melting point of 2054°C and a boiling point of 2980°C. It is an ionic crystal that can ionize at high temperature and is often used in the manufacture of refractory materials.