Silicon carbide cyclone

Silicon carbide Cyclone Introduction

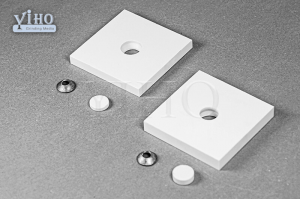

Replaceable silicon carbide cyclone and hydrocyclone liners are specifically engineered for classifying applications.

The Cyclone Yiho manufactured are mainly used in Coal mining.

Compared with other coal preparation methods, silicon carbide cyclone has its unique advantages, which can be summarized as follows:

• silicon carbide cyclone has the advantages of large processing capacity per unit volume, high separation accuracy and low separation particle size limit, which can be used for raw coal separation with various washability. The unit capacity of cyclone is much higher than other gravity separation equipment.

• Less investment and convenient management. The traditional view is that the dense medium coal preparation system is complex, the equipment wear is serious, the maintenance quantity is large, the management is difficult, the coal preparation cost is high, and so on. However, with the continuous improvement of dense medium coal preparation technology, especially the advent of three product heavy medium cyclone, and the emergence of corresponding auxiliary equipment and reliable wear-resistant materials, the above understanding has fundamentally changed.

• The small size of the plant and the compact and neat layout of the equipment make it convenient for the construction of the coal preparation plant to realize the scale and greatly shorten the construction period of the coal preparation plant.

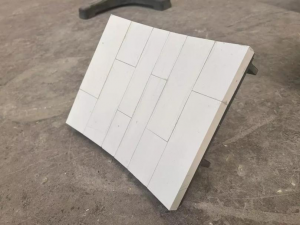

Reaction bonded silicon carbide is a multi-phased material typically containing 7-15% silicon metal, some minor amount of unreacted carbon, with the remaining body being SiC. Reaction bonded SiC materials are manufactured utilizing a variety of processes depending on desired final product geometry, configuration, and required tolerances.

Reaction bonded silicon carbide has proven to be an excellent material choice for wear applications such as pipe liners, flow control chokes and larger wear components in the mining as well as other industries. CALSIC RB offers an economical and reliable material option for many applications where the corrosion resistance or wear resistance of CALSIC S (sintered silicon carbide) is not necessary.

Typical properties of silicon carbide

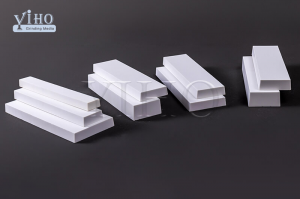

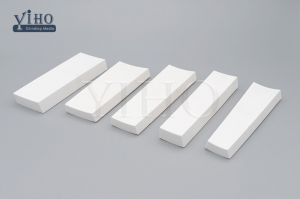

Kiln furniture for powder metal and ceramic processing

Kiln components including:

hearths

entrance tiles

skid rails

muffles

side walls

arches

Reaction Bonded Silicon Carbide Properties

|

Item |

Unit |

Data |

|

Temperature of application |

℃ |

1380℃ |

|

Density |

G/cm3 |

>3.05 |

|

Open porosity |

% |

<0.1 |

|

Bending strength -A |

Mpa |

250 (20℃) |

|

Bending strength -B |

MPa |

280 (1200℃ ) |

|

Modulus of elasticity-A |

GPa |

330(20℃) |

|

Modulus of elasticity -B |

GPa |

300 ( 1200℃ ) |

|

Thermal conductivity |

W/m.k |

45 (1200℃ ) |

|

Coefficient of thermal expansion |

K-1 ×10-6 |

4.5 |

|

Rigidity |

/ |

13 |

|

Acid-proof alkaline |

/ |

excellent |