Sintered Alumina Tiles for high-wear applications

Alumina Wear Tiles Introduction

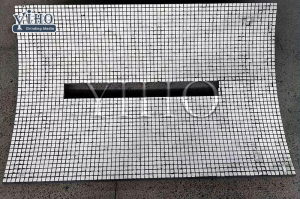

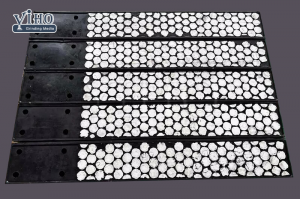

Alumina Wear linings are protective covers installed in areas subjected to wear. They are widely utilized in mining, aggregates and cement industries processing hard materials that are tough on equipment. The right wear lining prolong the lifetime of equipment, improve material flow, reduce noise, and thus increase the production capacity.

★Alumina Ceramic Tile linings Applications

Be used in Coal, petroleum, steel, coal fired power generation industries, etc. As the wear-resistant liner to protect the surface of the transport equipment being worn.

★Alumina Ceramic Tiles Features

Being fired under high temperature, wear-resistance, shock resistance, acid and alkali resistance, its theory wear-resistance is equivalent to 260 times of manganese steel, 170 times of chromium steel, can enhance the life time of equipment.

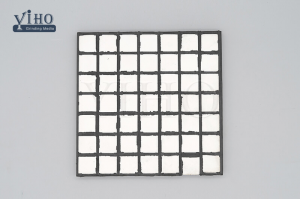

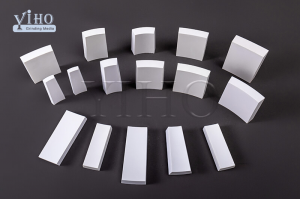

★Size(We could produce as your required)

Alumina Ceramic Tiles deliver superior wear resistance, excellent mechanical and anti corrosion properties. Yiho can supply alumina tiles in a variety of standard sizes and shapes that can be installed easily and economically in any situation. It is recommended that Ceramic Tile Adhesive be used for attaching the Alumina tiles where applicable.

|

Item |

(Length) mm |

(Width) mm |

(Thickness) mm |

Note |

|

150×100 |

150 |

100 |

6-50 |

Flat tile |

|

150×100 |

150 |

100 |

12-20 |

Welding tile with hole |

|

100×100 |

100 |

100 |

6.5-15 |

Flat tile |

|

10×10 mat |

10 |

10 |

3-10 |

Square |

|

17.5×17.5 mat |

17.5 |

17.5 |

4-10 |

Square |

|

20×20 mat |

20 |

20 |

3-20 |

Square |

|

11.55×11.55 mat |

11.55 |

11.55 |

3-10 |

Square |

|

12.5×12.5 mat |

12.5 |

12.5 |

3-10 |

Square |

|

50×50 |

50 |

50 |

5-15 |

Flat tile |

|

120×80 |

120 |

80 |

6-20 |

Welding tile with hole |

|

150×60 |

150 |

60 |

10-25 |

Flat tile |

|

100×81.6/78.5 |

100 |

81.6/78.5 |

20 |

Curved tile |

Alumina Wear Tiles Technical Data

Yiho can provide the ceramic tile with alumina content from 92% to 99%

|

Category |

HC92 |

HC95 |

HCT95 |

HC99 |

|

Al2O3 |

≥92% |

≥95% |

≥ 95% |

≥ 99% |

|

ZrO2 |

/ |

/ |

/ |

/ |

|

Density (g/ cm3 ) |

>3.60 |

>3.65g |

>3.70 |

>3.83 |

|

HV 20 |

≥950 |

≥1000 |

≥1100 |

≥1200 |

|

Rock Hardness HRA |

≥82 |

≥85 |

≥88 |

≥90 |

|

Bending Strength MPa |

≥220 |

≥250 |

≥300 |

≥330 |

|

Compression strength MPa |

≥1050 |

≥1300 |

≥1600 |

≥1800 |

|

Fracture Toughness (KIc MPam 1/2) |

≥3.7 |

≥3.8 |

≥4.0 |

≥4.2 |

|

Wear Volume (cm3) |

≤0.25 |

≤0.20 |

≤0.15 |

≤0.10 |

Alumina Ceramic Wear Tiles Application

Industrial Ceramics Alumina Tiles provide excellent abrasion and impact resistance for Mining and Industry applications. If abrasion resistance and impact resistance are a problem at your installation you can be sure that our wear solutions and Industrial Ceramic Tiles will assist to help extend the life of your bulk handling equipment and keep your systems operating at maximum levels.

• Bulk material handling

• Steel industry

• Thermal power plants

• Coal Mining