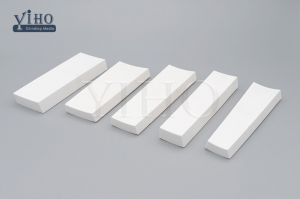

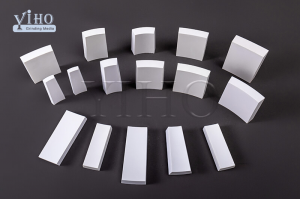

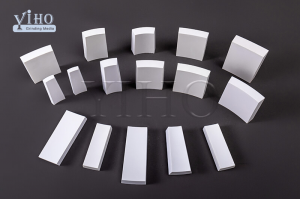

Standard Alumina Tiles

-

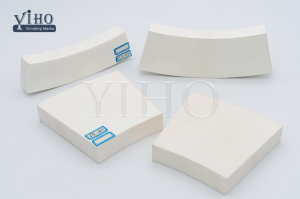

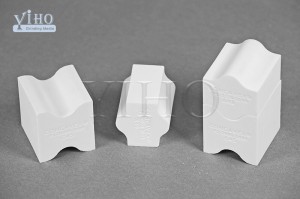

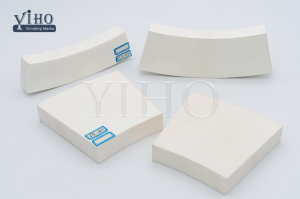

Alumina Curved Pipe Tile Liner

Curved pipe tile liner is a excellent wear-resistant material mainly pasted on the inner wall of pipeline or cyclone.It can reduce the wear and tear of the equipment and prolong its service life.

-

ZTA Ceramic Cyclone Lining plate

Zirconia Toughened Alumina Ceramics also named ZTA ceramics, zirconium oxide ceramics, which is white, corrosion resistance, chemical stability,a special combination of aluminum oxide and zirconium oxide.

-

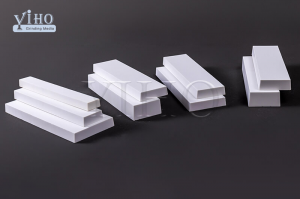

Trapezoidal Tile Alumina Ceramic Pipe Tile Lining

Trapezoidal pipe ceramic lining plate is suitable for wear-resistant lining of pipes and elbows with a diameter of less than 900mm.

-

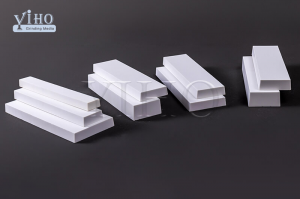

Sintered Alumina Tiles for high-wear applications

Alumina Wear linings are protective covers installed in areas subjected to wear. They are widely utilized in mining, aggregates and cement industries processing hard materials that are tough on equipment. The right wear lining prolong the lifetime of equipment, improve material flow, reduce noise, and thus increase the production capacity.

-

High purity oxide alumina ceramic tiles

Yiho premium alumina ceramics are manufactured by blending and mixing specified ratios of high-quality raw materials such as alumina powders, oxides, lubricants, dispersion agents, binders and water using a ball mill method. The slurry then goes through a spray drier before the pressing stage. Low percentages of organic binders allow the alumina particles to bond together and form a green un-sintered body during the pressing stage. Once pressed to size, pre-heating takes place followed by sintering through a tunnel kiln. Sintering temperatures and times are strictly followed to ensure binder burn out is optimized and that explosive spalling does not take place.

-

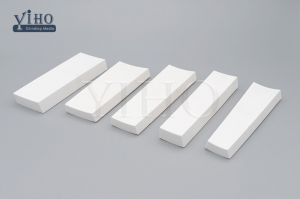

High alumina Weld-on wearing tiles

Ceramic tiles have excellent abrasion and wear resistant qualities and are ideal for use in transfer chutes, piping systems, hoppers, etc. Typical markets include grain, coal-fired power generation, mining, cement, and more.

-

High alumina Ceramic Wear resistant Tiles

Alumina ceramic tiles for coal and other material handling and processing industries. Ceramic linings provide long-lasting solutions to the problems caused by abrasive wear and corrosion in a variety of hostile environments. Alumina ceramic linings will outlast lower grade materials commonly used to line or protect processing and material handling equipment, including Basalt, stainless steel, carbon steel and wear resistant plates, by factors of 3 to 15 times.

-

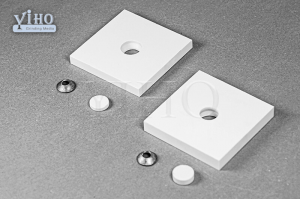

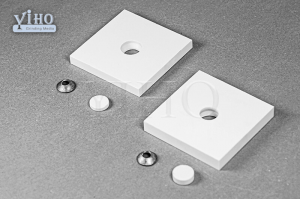

Coal Mining Ceramic Perforated Lining Plate Weldable Tile

YIHO supply and install a wide range of Alumina Wear Resistant Tiles for wear protection of all areas such as Chutes, Silos, Feeders, Bins, Launders, Dutching, Tanks, Bunkers, Hoppers, Underpans etc.

-

92% /95%/99% Al2O3 Ceramic plain Tile

Ceramic Alumina Tiles are specially designed using industry expertise to combat the effects of wear on your mineral processing and bulk handling equipment. Our high-content Ceramic Alumina Tiles, with a fine crystalline structure.

-

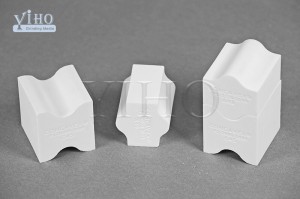

Impact Ceramic Block/Cube

The Ceramic Cube is a high-performance abrasion and impact resisting linings for high-impact, high-pressure applications in which ceramic tile may not have sufficient structural resistance, and high-performance rubber may not offer the required wear life. In extreme applications, the Cube liners can be installed in a matrix or abrasion resistant steel plate to provide structural support for the ceramic/rubber matrix and provide exceptional wear life where competing products cannot.

-

Industrial ceramic wear tiles

Wear-resistant elements prevent destruction in the transportation, processing, mining and other technological equipment. The elements are made of high-purity, finely dispersed, alpha-alumina. Wear-resistant plates can be made from a variety pre-designed element of different dimensions and forms.

-

Wear and Impact Resistant Conveyor Chute Wear Liner Alumina Ceramic Rubber Wear Plate

Conveyor Chute Wear Resistant Ceramic Rubber Liner is made of high alumina ceramics and high-quality natural rubber compounded by a special process.