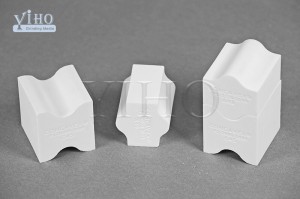

Steel backed Weldable Ceramic Tiles composite wear mats

Impact and Abrasion - Why Use Composite Ceramics?

Composite Ceramic Wear Mats consistently

demonstrate and prove to be the lowest cost per

tonne wear liner on the market.

• Very High Quality Rubber and Ceramic

• Competitively Priced

• Designed ‘Fit for Purpose’ Wear Liners

• Single Liners or Kits

• Complete design and Technical Support

• Energy absorbent Design

• Extended WEAR Life compared to steel liners

The steel backed ceramic Mats have superior wear resistance. Liners comprising of high alumina ceramics and energy-absorbing rubber cushions which are more impact resistant. These features will also extend the wear life of your production line, and reduce maintenance and downtime.

Ceramic Wear mats are reinforced with a vulcanized steel backing plate for stability in the most demanding applications. This vulcanized steel backing allows for extremely strong mechanical fastening to equipment.

The liners can be customized depending on the application.

* All ceramic mats are supplied with a bonding

layer so no buffing / preparation is required for

installation on site.

Selection guide for rubber ceramic Mats

-Material Type: coal, rocks, gold slurry, iron ore, etc.

-Particle Size

-Drop height

-Sliding wear or impact wear, impact angle

-The current liners used and its life time.

-Required life-time.

Ceramic Wear Mats have been designed primarily for use as a wear protection ceramic lining system.

They are installed into equipment to protect steel surfaces from abrasion and impact. Ceramic Wear Liners are predominantly used in the Mining, Quarrying and Mineral processing industries, typically on the following equipment:

• Chutes and Feed Spouts

• Hoppers and Surge Bins

• Skips and Flasks for Underground Mining

• Feeders

• Cyclones

• Launders

• Screens

• Conveyor Transfer Chutes and Deflector Plates

• Sumps and Underpans

Ceramic Tile TECHNICAL INFORMATION

| Alumina Ceramic Tile Data | ||

| Alumina Content | 92% (min) | |

| Density | 3.65 gr/cm3 | |

| Hardness (Rockwell) | 82(min) | |

| Compressive Strength | 1050 Mpa (min) | |

| Flexural Strength | 220Mpa (min) | |

| Water Absorption | 0.1% (max) | |

| Abrasion by Impingement | 0.05 grams (max) | |

| Abrasion by Rubbing | 0.1 grams (max) | |

| RUBBER Data | ||

| Polymer | SBR | |

| Colour | Black | |

| Hardness (Shore A) | 60° ± 5° | |