Surface protection engineered solution Wear Ceramics pipe and Pipe Fittings

Product introduction

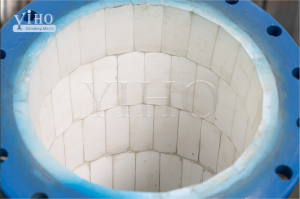

Wear-resisting ceramic-lined pipe can be applied to the pipeline transport of materials, in the long-term pipeline transport, the pipe wear is serious, especially pipe elbow, often because of long-term wear and tear caused by the pipe damage, pipe elbow impact force is large, wear is serious.

Ceramics have excellent impact resistance and super wear resistance, usually used in the inner wall of the pipe and equipment, to protect the pipe, reduce wear, impact resistance.

The wear-resisting ceramic lining is installed in the inner wall of the pipeline in the form of pasting, welding, dove-tail and so on to form a firm anti-wear layer. With its super wear resistance, it is widely used in pneumatic conveying and hydraulic conveying systems in industrial enterprises.It is widely used especially in the environment with severe impact corrosion.

Advantage Of the Ceramic Wear Lining

- Longer service life

- Temperature resistance and aging resistance

- Light weight

- The surface is smooth

- Ceramic staggered joint installation

- Easy installation

Technical data of Alumina Ceramics

|

Category |

HC92 |

HC95 |

HCT95 |

HC99 |

HC-ZTA |

|

Al2O3 |

≥92% |

≥95% |

≥ 95% |

≥ 99% |

≥75% |

|

ZrO2 |

/ |

/ |

/ |

/ |

≥21% |

|

Density (g/ cm3 ) |

>3.60 |

>3.65g |

>3.70 |

>3.83 |

>4.10 |

|

HV 20 |

≥950 |

≥1000 |

≥1100 |

≥1200 |

≥1350 |

|

Rock Hardness HRA |

≥82 |

≥85 |

≥88 |

≥90 |

≥90 |

|

Bending Strength MPa |

≥220 |

≥250 |

≥300 |

≥330 |

≥400 |

|

Compression strength MPa |

≥1050 |

≥1300 |

≥1600 |

≥1800 |

≥2000 |

|

Fracture Toughness (KIc MPam 1/2) |

≥3.7 |

≥3.8 |

≥4.0 |

≥4.2 |

≥4.5 |

|

Wear Volume (cm3) |

≤0.25 |

≤0.20 |

≤0.15 |

≤0.10 |

≤0.05 |

Application of Ceramic Lined Pipes

| 1. Abrasive products | Grinding wheel granules |

| 2. Aluminium plants | Calcined alumina, bauxite, electrode, carbon, crushed bath |

| 3. Iron & Steel | Sinter dust, limestone, lime injection, coal, iron carbide, alloy additives |

| 4. Mineral wool & insulation products | Perlite, stone dust, refractory fibers, production wastes, dust from sawing operations |

| 5. Foundries | Molding sand, dust collection |

| 6. Glass plants | Batch, cullet, quartz, kaoline, feldspar |

| 7. Breweries, grain processing, feed mills | Corn, barley, soy beans, malt, cocoa beans, sunflower seeds, rice hulls, malting plants |

| 8. Cement | Clinker dust, limestone, cement, fly ash, coal, blast furnace slag |

| 9. Chemical plants | Caustic lime, fertilizers, lime dust, chrome ore, paint pigments, plastic pallets with glass fi bers |

| 10. Mineral mining plants | Kiln feed, ore concentrate, coal tailings, dust |

| 11. Coal fired power stations | Coal, fly ash, pyrites, slag, ash, limestone |

| 12. Coal mines | Coal dust, mine waste for back filling |

| 13. Technical carbon products | Technical carbon, dust, graphite for electrodes |

Housing Materials

• Carbon Steel

• Stainless Steel

• Alloys