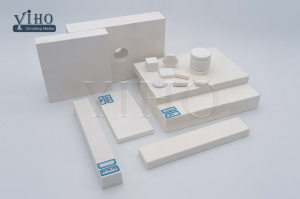

Wear Resistant Rubber Ceramic Panels

Wear Resistant Rubber Ceramic Panels Introduction

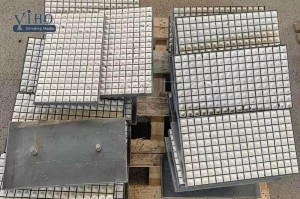

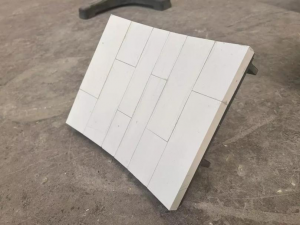

Wear Resistant Rubber Ceramic Panels is new generation composite panels, a combination of wear resistant alumina ceramic Hexagonal ceramic tiles vulcanized in resilient rubber base. The alumina ceramic surface provides exceptional resistance to wear, while the elastic property of the rubber effectively dampens the impact forces which can crack the ceramics. Rubber also helps to substantially reduce the vibrations, sounds, and the impact shock generated from impacting rocks. Laid out in zigzag and brick pattern, ceramic tiles/cylinders is an excellent feature for handling large material volumes at different angles without developing a wear pattern. As excellent impact and wear resistant material,The panel is suitable for feeders, chutes, bins, transfer points, in conveyor systems, screen feed plates, mill discharge chutes, bunker etc. The major applicable industries are Coal fired power plants, cement plants, blast furnace plants and host of other industries which requires high impact abrasion resistant surfaces.

Data of Ceramics

|

Type of Ceramics |

Rubber |

Steel/Metal |

|

92% Alumina |

Natural rubber Hardness 60 |

A235A |

|

95% Alumina |

|

|

|

99% Alumina |

|

|

|

ZTA |

|

|

|

Zirconia |

|

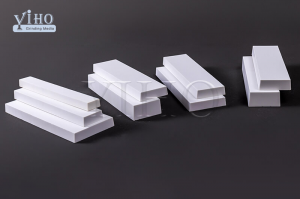

Hexagonal Ceramic Tile Liner Regular Sizes

|

Panel Size |

300×300,250×250,500×500,600×600mm |

|

Ceramic size |

19x19, 21x21, 40x40 Hex tile |

|

Alloy Steel Size |

alloy steel plate with thickness ranging from 3 mm to 10 mm |

|

Rubber Thickness |

Depends upon the impact stress expected. |

|

Remark |

metal+rubber+ceramic / rubber+ceramic plain surface or spherical surface. The steel bolt also available upon requests |

Hexagonal Ceramic Tile Liner Advantages

1) Small and flexable size. It can suitable most of irregular equipment.

2) High alumina content and high hardness:

Its rockwell hardness is HRA80-90 and the Moh's hardness is up to 9 grade with is only less than diamond. And its abrasion-resistant is more better than steel and stainless steel;

3) Excellent abrasion resistance and impact resistance.

4) Excellent corrosion resistance (resist the strong alkaline, strong acid slag and liquefied materials).

5) Excellent heat resistance (up to 1500 ℃).

6) Smooth surface can be reduce barrage and friction coefficient to prolong the device service life.

7) Low density reduce the lined equipment weight and improve the equipment working effectiveness

8) Light weight:

Alumina Ceramic density is 3.6-3.75g/cm3, it is only half weight of steel, and could reduce the load on equipment.

Hexagonal Ceramic Tile Liner Application

Our Alumina ceramic liners will outlast lower grade materials commonly used to line or protect processing and material handling equipment by factors of 3 to 15 times. Tile liners are often used in grain transitions, grain spouts, grain elbows, grain chutes, grain conveyors, hopper bins, grain valves and grain gates.

Hexagonal Ceramic Tile Liner Packing

Wooden Crate | Ply-Wood Pallet