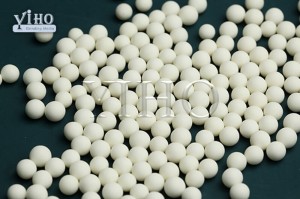

Yttrium Stabilized Zirconia Milling Media

What are Yttrium Stabilized Zirconia Beads?

Yttrium stabilized zirconia beads are highly efficient and durable media for attrition and ball milling of ceramic materials. These zirconia beads provide a long-lasting, contamination-free solution for the ceramic grinding and milling industry.

Zirconia’s higher density compared to glass and alumina creates a high grinding efficiency and greatly reduced grinding time. The zirconia beads are perfect for use in wet grinding and high-velocity operations.

Yttrium Stabilized Zirconia Beads Applications

Yttrium stabilized zirconia beads are crucial in advanced industries due to their exceptional durability and density. Predominantly, they're used as high-end grinding media in pharmaceutical, paint, and ink production, enhancing dispersion efficiency.

In addition, zirconia beads are essential to lab milling operations and magnetic materials based on iron and chrome. The spherical beads are also applied in ceramic matrix composites for high-temperature resistance and in solid oxide fuel cells due to their excellent ionic conductivity.

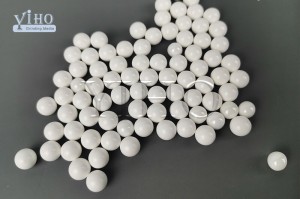

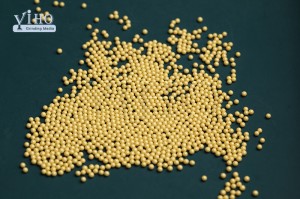

Zirconia beads are available in different sizes, as you see below. We also offer custom zirconia milling media to meet your requirements. We can provide you with zirconia beads in both cylindrical and spherical forms. Request a quote today.

The Benefits of Yttrium Stabilized Zirconia Beads

Yttrium stabilized zirconia beads offer significant benefits. Their high density and hardness contribute to superior grinding efficiency, reducing process times in industries like pharmaceuticals and paints. They display excellent wear and friction resistance, enhancing longevity in high-impact environments. The zirconia beads’ excellent thermal stability and ionic conductivity are also ideal for applications in high-temperature ceramic composites and solid oxide fuel cells.

Zirconia beads’ high elastic modulus and robust mechanical, chemical, and thermal resistance ensure durability under extreme conditions. Strong electrical insulating properties make them ideal for electronic applications, while their low porosity enhances wear resistance. Moreover, zirconia milling media’s thermal stability and ionic conductivity make them suitable for high-temperature ceramic composites and solid oxide fuel cells.

Choosing zirconia beads gives your company several advantages. One is low service cost, which occurs as it decreases the cost of power consumption, equipment, labor, and media abrasion. It also results in significant improvements in product quality.