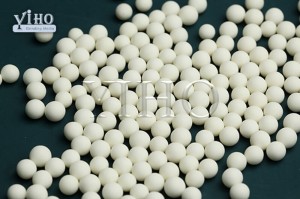

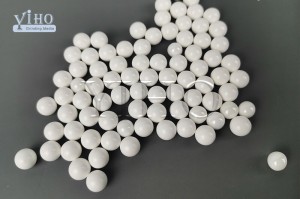

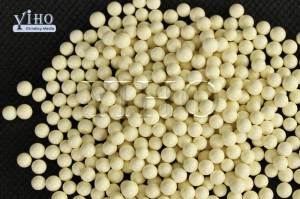

ZTA Ceramic Grinding Balls

Comparison with other Ceramic Grinding Media

* Compared with zirconium grinding media, the one-time investment is less;

* Compared with the general high aluminum ball, the density is larger, and the grinding efficiency is high;

* Compared with high-aluminum balls at the same price, the wear is lower, and the cost performance is high;

* High hardness, high strength and low crushing rate;

* The size is relatively complete, which can be applied to different industries and different equipment requirements.

ZTA (ZrO2-Al2O3) Medium Density Ceramic Grinding Media

ZTA Grinding Balls Features

-Optimal density

-Compatible with all mill types

-No breakage of the grinding media

-Higher milling efficiency

-Low wear rate

-Economic advantage

ZTA Grinding Balls Applications

-High Tech ceramics

-Contamination free milling

-Special Products or raw material preparation

- Technical ceramics

-Pigments. Paints

-Dielectric materials

- Electro ceramics -

-Production of printing and inks

-Piezoelectric materials

- Refractory materials

- Coatings

- Magnetic Materials

- Coating Materials

- Paper industry

- Minerals

- Agro Chemicals

ZTA Grinding Balls Packing

1. 25kg/bag,40bags on 1 pallet (Plywood pallet)

2. 1000kgs/jumbo bag, 1 bag packed on 1 pallet. (Plywood pallet)

3. 2000kgs/jumbo bag, 1bag packed on 1 pallet. (plastic pallet)

4. 1000kgs/jumbo bag in ply-wood crates

Other

ZTA Grinding Balls Delivery

The grinding media is delivered in container of 20’FCL.

ZTA Grinding Balls Storage

The grinding media should be stored in a dry and clean place.

ZTA Grinding Balls Support

Please do not hesitate to contact us if you need further technical information about milling processes or applications.